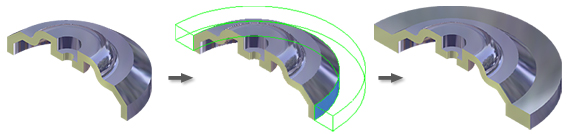

The Thicken/Offset command adds or removes thickness from parts and creates offset surfaces from part faces or other surfaces . When you select Output, you determine if the feature is a solid, a surface, or a new solid body. If you select Surface, the result is an offset surface. If you select Solid, the result is a thicken feature. If you select New solid, the result is a new body in a multi-body part. Each feature type is shown in the browser with a unique icon.

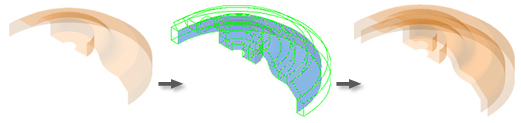

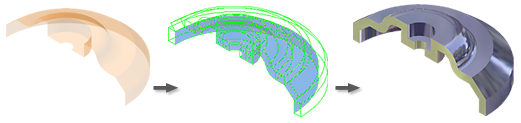

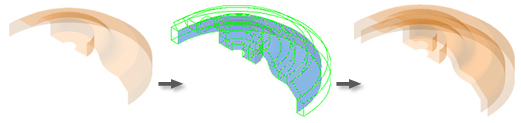

The following images show various thicken or offset solutions.

Thicken adds or removes material from the model and therefore changes its mass properties. When you add thickness to a surface, the model is converted from a surface to a part.

By default, Autodesk Inventor provides a precise offset feature. When a precise solution does not exist, an approximation is attempted.

Can faces and surfaces be selected together?

No.

Thickened faces and offset surfaces cannot be created in one feature. Thickness features and offset features have individual icons in the browser.

Can I edit an offset feature and convert it to a thicken feature?

No. You cannot use Edit Feature to change an Offset Surface feature to a Thicken feature or vice versa. The feature type is determined by your selection of the output type. Offsets are surface features while thicken is a part feature. Each feature type creates an individual icon in the browser.

You can, however, thicken an offset surface. This operation places a thicken icon below the offset surface icon in the browser.

What surfaces can be offset?

Surfaces created in Autodesk Inventor or imported surfaces can be used for an offset. Imported surfaces must be promoted to the part environment. they cannot be thickened or offset in the construction environment .

Surfaces must be adjoining to be offset at the same time. The offset result is a copy of the selected geometry (such as face, fillet, adjacent face, and so on).

Vertical surfaces can only be created from the internal boundaries of a quilt face.

When importing complex surfaces, you can experiment with the file format. IGES and SAT files are commonly used formats when converting models you receive from a vendor, for example.

How do precise and approximate solutions differ?

In a precise solution, each point of the original surface has a corresponding point on the offset surface. The distance between the two points is equal to the specified distance. An approximate solution enables Autodesk Inventor to deviate from the specified distance to find an acceptable solution.

You can control where the deviation is allowed to occur, as well as the accuracy of the approximation. Keep in mind that the more accurate the approximation, the longer it takes to compute. Approximate solutions are provided only when a precise solution does not exist and when an approximate solution can be found. If approximate solutions are not acceptable, you can turn this option off.

Each time approximation is used, the tolerance of the deviation is reported.