In this section, you use Parting Diagnostics before creating the core and cavity to verify that the parting surface has been completed successfully. You then generate the core and cavity for the model.

If there is a problem with the parting surface, such as a leak due to a hole or breach, the problems list. You can highlight the potential problem areas in the graphics window by selecting them in the list.

- On the ribbon, click Core/Cavity tab > Parting Design panel > Generate Core and Cavity

.

.

On the dialog box, choose Preview/Diagnose to start the parting analysis. Click the Parting Diagnostics tab. The Problems list in the dialog box indicates that there are some undercut faces in the model. It indicates to use Inserts for these faces to ensure that the product can be ejected smoothly. You learn how to create Inserts in the Mold Structural Assembly tutorial. For now, continue with this topic.

- Click the Preview tab.

- Rotate the model. Notice that the core and cavity bodies are blue and green.

- Green indicates the cavity body which has a positive draft angle in the pull direction.

- Blue indicates the core body which has a negative draft angle in the pull direction.

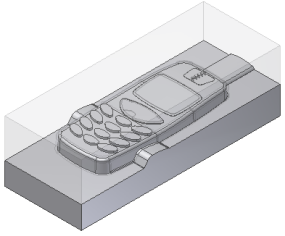

- Drag the Body Separation slider all the way to the right. The core and cavity bodies separate, as shown in the following image. The Surface Separation slider shows you what the core and cavity bodies will look like. It helps you detect potential errors in the parting design before the actual parts are generated. In this design, the core and cavity bodies are satisfactory.

- Click OK to generate the core and cavity.

- Click OK to accept the defaults on the File Naming dialog box.

- The system removes the driving moldable part from display and the core and cavity set are shown. The core body is opaque and the cavity body is translucent.

- On the Quick Access toolbar, click Save to save the assembly.