Overrides default parameters that define how corners are relieved when a folded model is unfolded. Change these parameters for individual features using the Corner Options tab. The Default settings are specified in the Sheet Metal Styles dialog box.

| Access: | |

|---|---|

|

Click the Corner tab on the Contour Flange, Flange, or Corner Seam dialog box. Note: Not all options described are available or valid for each feature that shares this tab.

|

|

|

Use this option to define the Default corner relief when two bends intersect. |

|

|

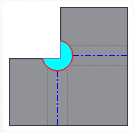

Round A corner relief shape defined in the flat by a circular cut out centered on the intersection of the bend lines. |

|

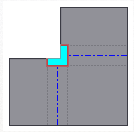

Square A corner relief shape defined in the flat by a square cut out centered on the intersection of the bend lines. |

|

Tear A corner relief shape defined in the flat by extending the flange edges to their intersection. Characterized by no relief which allows material failure (tearing) across the bend zone in the folded model. |

|

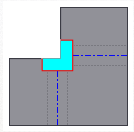

Trim to Bend A corner relief shape defined in the flat by a polygonal cut out bounded by the bending zone lines. |

|

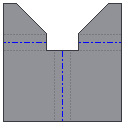

Linear Weld A corner relief shape defined in the flat by a V-shaped cut out defined from the intersection of the inner bend zone lines to the outer bend zone intersection of the line with the flange edges. Characterized by minimum relief allowing a subsequent weld operation to close the corner. |

|

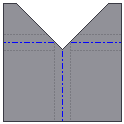

Arc Weld A corner relief shape defined in the flat by curves tangent to the flange edges along the outside edge of the bend zone which converge to a flat gap equal to the Miter Gap value. Characterized in the folded model by a gap between the flanges that is equidistant along the length of the relief suitable for subsequent arc welding. |

|

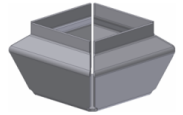

Use this option to define the Default corner relief to display in the flat pattern when three bends intersect. Note: The folded model does not display the selected relief option.

|

|

|

No Replacement As indicated, no replacement of the "as modeled" geometry is made in the flat pattern. |

|

Intersection A corner relief shape defined in the flat by extending and intersecting the flange edges. |

|

Full Round A corner relief shape defined in the flat by extending the flange edges to their intersection and then placing a fillet tangent to the bend zone tangency lines. Radius are likely larger than what is produced using the Round with Radius option. |

|

Round with Radius A corner relief shape defined in the flat by extending the flange edges to their intersection, and then placing a tangent fillet of the size specified. Radius likely smaller than what is produced by the Full Round option. |

Relief Size - Allows you to input a value to change the size of the Corner Relief of the selected feature from the default which is defined in the Sheet Metal Style using the named parameter: CornerReliefSize.

Apply Auto-Mitering - Enables automatic material extension between adjacent flange edges during creation or edit of at least two flange edges during a single operation where bend angle is greater than 90 degrees. Available on Flange and Contour Flange dialog box (not available on Corner tab of Corner Seam dialog box)

|

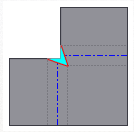

Enabled - A contour flange loop applied with the auto-miter option enabled. |

|

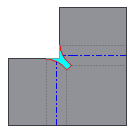

Disabled - A contour flange loop applied with the auto-miter option disabled. |

Miter Gap - Allows you to input a value to change the size of an automatically applied gap between flanges when the Auto-Miter option is enabled. When enabled, the value displayed defaults to the system named parameter GapSize, which is defined in the Sheet Metal Style.

2 Bend/3 Bend Corner - Indicates which type of corner relief applies to the selected geometry. These options are active when a choice must be made between the type of corner being specified. They are inactive and serve as an indicator of the type of corner selected at all other times.