Next, create a leg from the skeleton part and then ground it in the assembly.

- On the ribbon, click

Assemble tab

Component panel

Component panel

Create

.

Create

. - Enter Leg as the part name, and base the part on the Standard(mm).ipt template.

- Click OK in the Create In-Place Component dialog box.

- Expand the Origin folder under Skeleton.iam in the browser. Click the XY Plane node. It aligns the part origin to the assembly origin.Note: This step is critical to aligning all parts based on the skeleton model.

- Exit the sketch in the new part, and then delete Sketch1 to tidy up the Model browser.

- Use the Derive command to derive the SkeletonBase.ipt part into the Leg part.

- Exclude all sketches other than VERTICAL LEGS SKETCH.

- Expand Work Geometry in the Derived Part dialog box, and exclude all work features other than Work Plane-BOTT of Frame.

- Exclude Surface Bodies and Parameters from the derived component.

- Click OK.

- Click

3D Model tab

Create panel

Create panel

Extrude

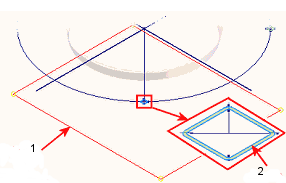

. Extrude the tube profile highlighted in the following illustration.

Extrude

. Extrude the tube profile highlighted in the following illustration.- Click the Extents button flyout arrow in the Extrude mini-toolbar, and select To selected face/point. Then, click the derived work plane in the graphics window.

- Click the green Ok button to complete the feature.

1 - Extrude to workplane

2 - Profile

- Expand SkeletonBase.ipt in the Model browser. Right-click Work Plane - BOTT of Frame, and remove the checkmark next to Visibility.

- Finally, return to the assembly environment. Right-click Leg in the Model browser and select Grounded from the pop-up context menu.

- Save the assembly.