Before going further in the tutorial, it is good to understand the differences between the assembly modeling and dynamic simulation environments.

Though both environments have to do with creating mechanisms, there are some critical differences between Dynamic Simulation and the Assembly environment. The basic difference has to do with degrees of freedom and how they are managed.

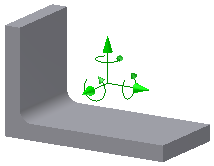

In the assembly environment, unconstrained and ungrounded components have six degrees of freedom.

You add constraints to restrict degrees of freedom. For example, adding one flush constraint between this part and one of its canonical planes removes 3 degrees of freedom.

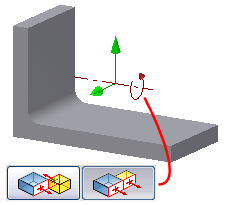

In Dynamic Simulation, unconstrained and ungrounded components have zero degrees of freedom and will not move in a simulation. The addition of joints creates the degrees of freedom. When entering Dynamic Simulation, components that have mate constraints receive these joints automatically.

With either Dynamic Simulation or the assembly environment, the intent is to build a functional mechanism. Dynamic Simulation adds to that functional mechanism the dynamic, real-world influences of various kinds of loads to create a true kinematic chain.