In the first portion of this tutorial, you will create a simple sheet metal guard. You create the guard in the assembly using projected geometry and measurements of assembly components. This workflow ensures that the guard will be sized correctly.

There are other ways to start a design. Before you begin the steps of the tutorial, let’s review a typical workflow that produces a similar model:

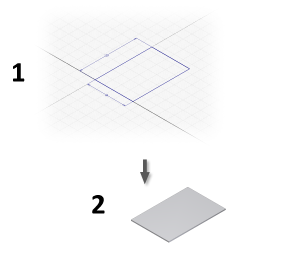

- A common first step is the creation of a closed profile sketch.

- Using this closed profile sketch, a sheet metal Face feature is created as the base feature of the model.

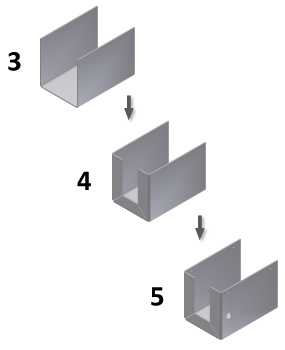

- Once a base Face feature exists, Flange features can be added.

- Additional Flange features with automatic mitering can be added to existing Flange features.

- Finally, a series of Hole features can complete the model.

Using a Face feature as the base feature is very common in a stand-alone design workflow. However, the sheet metal part that you are creating will often need to fit inside or over existing parts in an assembly. In the next portion of the tutorial, you open an existing assembly and create a part like the one illustrated. You will use geometry selected in the assembly to determine the size and position of the features that you will create.