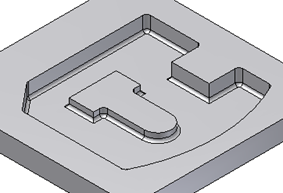

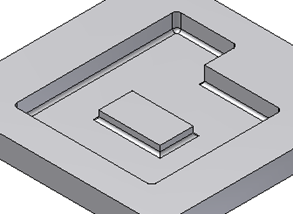

To fillet the pocket to model a milling process with a tool of 3 mm. diameter and 1 mm. cutting radius, all the concave vertical edges must have a fillet of 1.5 mm. radius (generated by the vertical approach of the tool), while the edges of the bottom face must have a fillet of 1 mm. radius corresponding to the tool cutting radius

- On the ribbon, click

3D Model tab

Plastic Part panel

Plastic Part panel

Rule Fillet

Rule Fillet

.

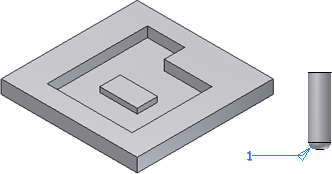

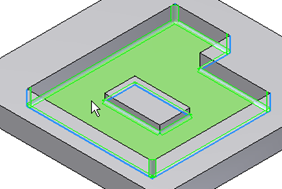

. - Set the Source to Face, and select the bottom face of the pocket.

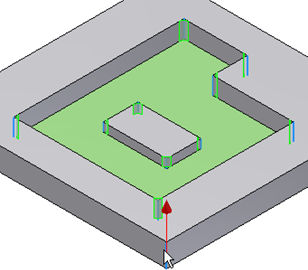

- Set the rule to Incident edges and select a vertical edge to define the axis.

- Verify that the direction is pointing up to include all the vertical edges that start from the selected face and go upward. If you try to flip to the opposite direction, no edge is selected. Enter a 1.5 mm. radius.

- When machining the pocket, if you do not want to round the convex edges, cancel the All Rounds option in the Options box.

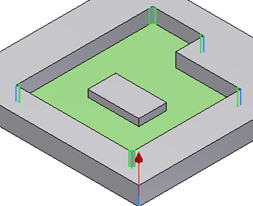

- Define the 1 mm. radius fillets of the bottom edges.

- “Click to add” a new rule. Set the Source to Face. Select the same face as in the previous rule, but now set the rule to All Edges.

- Enter a 1 mm. radius, and click OK to complete the rule-based fillet.

Even after a change in the pocket shape, the Rule-based fillet rebuilds correctly.