The combination of sprue, runners, and gates is used to transport the melt from the injection nozzle to the injection location for each part.

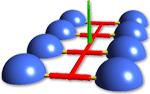

The design of the runner layout affects the amount of material used and the quality of the parts produced. If the flow within each cavity is unbalanced, overpacking and hesitation can lead to poor part quality. Long or poorly designed runners can cause large pressure drops and require a larger injection pressure to fill the part. The following diagram shows a typical runner system for a multi-cavity two-plate mold.

When designing the layout of the runner system, you must:

- Determine the number of cavities required

- Determine the material type

- Determine the processing conditions

- Adjust any flow leaders or deflectors as necessary

- Flow balance the cavities