The shape and diameter of the runners are important factors in successful mold design.

The shape of the runner affects the volume of material that remains molten, and the diameter affects the temperature of the melt in the runners and, thereby, the quality of the product and material waste.

Effects of shape

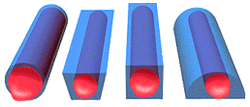

The cross-sectional shape of the runners affects the flow of the polymer through the runner system. When the hot melt hits the cold metal of the runner a layer freezes and forms a skin on the surface of the runner. The center of the runner remains molten while the polymer is being injected into the mold. The following diagram shows the molten core for different shaped runners.

A circular cross section provides the greatest proportion of polymer in a molten state. Runners with a curved or angular cross section require less force to remove from the mold than rectangular or square runners.

Although circular runners are the best choice for material flow and ejection, they are also the most expensive. This is partly because the runner needs to be cut into both plates and it is difficult to cut both halves of the runner so that they meet exactly.

A trapezoidal cross section can be used as a compromise. Trapezoidal runners often provide acceptable flow and ejection characteristics, and are cheaper to produce than round runners.

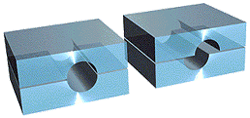

If you do decide to use a circular runner, extra care is needed to align the two halves of the circular runner to avoid an increase in injection pressure due to the reduced effective flow cross-section. In the following diagram, the runner on the left is correctly aligned, but the runner on the right will have a smaller molten center that will restrict flow.

Effects of diameter

A small runner diameter causes shear heating in the runners so the plastic temperature is higher in the runners than in the barrel. Higher melt temperatures reduce residual stress levels and the tendency of parts to warp, but high barrel temperatures can cause degradation of the material.

To minimize material waste and decrease the barrel temperature required, design the runners with a small cross-sectional area.

- Rapid changes in flow resistance

- Flow instabilities

- Increased injection pressure