Learn which analysis technology is appropriate for different types of parts.

If a model consists of thick sections, or the geometry of a thin-walled part yields unexpected results when using a Dual Domain analysis, then a 3D analysis is preferred.

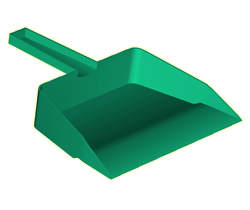

The dustpan model above consists of flat, shell-like surfaces and so should be suitable for Dual Domain analysis.

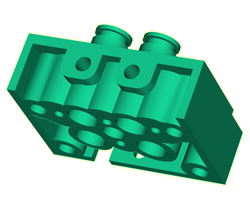

Due to the thick walls and complex shape, the part above would be most suitable for 3D analysis.

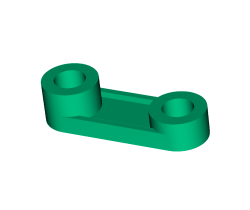

Most parts are a combination of thin sections and features that are thicker in nature. The part above has a thin center section that would be suitable for a Dual Domain analysis. The thicker bosses indicate a possible need for a 3D analysis.

On importing a model, the geometry of the part can be automatically investigated by selecting Check suitability in the Advanced options page of the Import wizard. The most suitable analysis type is then recommended for you.

Other design considerations such as how the finished part will be used, the injection location, or production problems may affect your choice of the most suitable analysis type.

At this stage either analysis type can usually be selected (3D is not available if the imported CAD model has defects that could not be automatically repaired). If at a later stage the alternate analysis technology is required, it is possible to switch between analysis type.

To switch between the analysis type:

- Right-click

Analysis Sequence in the Study Task panel.

Analysis Sequence in the Study Task panel. - Select Change to Dual Domain or Change to True 3D.

- If you are prompted with a dialog box asking if you want to convert the analysis type, click OK.

The option to switch between analysis type is only available in certain models. You are not able to switch between Dual Domain and True 3D if the model:

- Has not passed the defects check on import.

- Was imported from a *.adv file.

- Is a *.sdy file from MPA 8.0. Note: MPA 8.0 is an earlier version of Autodesk Simulation Moldflow Adviser.