Areas of the mold which cannot be cooled effectively by normal cooling channels may require the use of baffles. Baffles divert the coolant flow into areas that would normally lack cooling.

A baffle is a cooling system component which is constructed by inserting a metal plate in the cooling channels. The plate forces the coolant to flow up one side of the baffle and down the other. The baffle interrupts the flow in the cooling channels creating turbulence around bends which improves the heat transfer capability of the coolant.

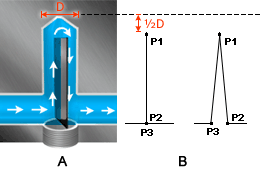

Baffles are modeled by creating two circular beam elements with a gap at the top for the coolant to flow around. The first circular element represents the flow up one side of the baffle and the second element is for the flow down the other side. Yellow is the default color assigned to a baffle. In the following diagram, A indicates the baffle cross-section and B indicates the mold model representation. The baffle is made up of two circular beam elements with HTE (Heat Transfer Effectiveness)=0.5.