- Click the

Home icon above the ViewCube for an isometric view of the model.

Home icon above the ViewCube for an isometric view of the model. - With the

Selection

Selection  Shape

Shape  Point or Rectangle and

Point or Rectangle and  Selection

Selection  Select

Select  Surfaces commands active, click one of the two cylindrical surfaces at the outside diameter of the piston.

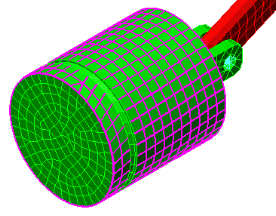

Surfaces commands active, click one of the two cylindrical surfaces at the outside diameter of the piston. - Hold down the Ctrl key and click the remaining outside diameter surface. The piston should appear as shown below.

- Hold down the Ctrl key and click the remaining outside diameter surface. The piston should appear as shown below.

- Click

Setup

Setup  Constraints

Constraints  General Constraint.

General Constraint. - Activate the Tx and Tz check boxes. The piston will only be free to translate in the Y direction.

- Click OK.

- Right-click the Part 3 heading in the browser (tree view) and choose Select Subentities

Surfaces. All the surfaces of Part 3 are now selected.

Surfaces. All the surfaces of Part 3 are now selected. - Click

Setup

Setup  Constraints

Constraints  General Constraint.

General Constraint. - Activate the Tx check box.

- Click OK. The crank will be free to move only in the Y and Z directions. Though not absolutely necessary, this constraint will stabilize the crank by preventing any twisting or bending due to flexure of the joints and will make convergence of the solution a little easier.