A beam element is a slender structural member that offers resistance to forces and bending under applied loads. A beam element differs from a truss element in that a beam resists moments (twisting and bending) at the connections.

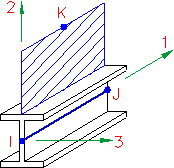

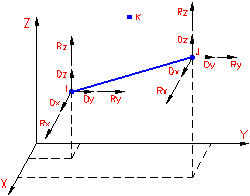

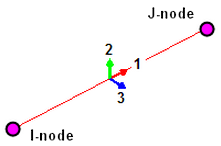

These three node elements are formulated in three-dimensional space. The element geometry specifies the first two nodes (I-node and J-node). The third node (K-node) is used to orient each beam element in 3D space (see Figure 1). A maximum of three translational degrees-of-freedom and three rotational degrees-of-freedom are defined for beam elements (see Figure 2). Three orthogonal forces (one axial and two shears) and three orthogonal moments (one torsion and two bending) are calculated at each end of each element. Optionally, the maximum normal stresses produced by combined axial and bending loads are calculated. Uniform inertia loads in three directions, fixed-end forces, and intermediate loads are the basic element based loadings.

Figure 1: Beam Elements

Figure 2: Beam Element Degrees-of-Freedom

For rotation about axes 2 and 3, only the m×R2 effect is considered, where R is the distance from the rotation point to the element. The mass moments of inertia, I2 and I3, are calculated based on the slender rod formula (I2 = I3 = M×L2/12).

The three mass moments of inertia only impact Natural Frequency (Modal) and Natural Frequency (Modal) with Load Stiffening analyses."

Use Beam Elements When

- The length of the element is much greater than the width or depth.

- The element has constant cross-sectional properties.

- The element must be able to transfer moments.

- The element must be able to handle a load distributed across its length.

Part, Layer, and Surface Properties for Beam Elements

The following table describes what controls the part, layer, and surface properties for beams.

|

Part Number |

Material properties and stress-free reference temperature |

|

Layer Number |

Cross-sectional properties |

|

Surface Number |

Orientation |

Beam Element Orientation

Most beams have a strong axis of bending and a weak axis of bending. Beam members are represented as a line, and a line is an object with no inherent orientation of the cross section. So, there must be a method of specifying the orientation of the strong or weak axis in three-dimensional space. The surface number of the line controls this orientation.

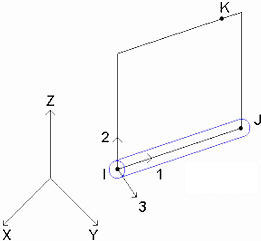

More specifically, the surface number of the line creates a point in space, called the K-node. The two ends of the beam element (the I- and J-nodes) and the K-node form a plane as shown in the following image. The local axes define the beam elements. Axis 1 is from the I-node to the J-node. Axis 2 lies in the plane formed by the I-, J- and K-nodes. Axis 3 is formed by the right-hand rule. With the element axes set, the cross-sectional properties A, Sa2, Sa3, J1, I2, I3, Z2, and Z3 can be entered appropriately in the Element Definition dialog box.

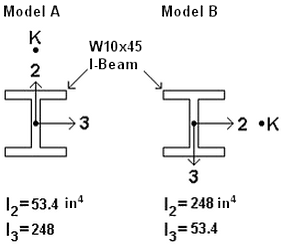

Axis 2 Lies in the Plane of the I-, J-, and K-nodes

For example, the following image shows part of two models, each containing a W10x45 I-beam. Both members have the same physical orientation. The webs are parallel. However, the analyst chose to set the K-node above the beam element in model A and to the side of the beam element in model B. Even though the cross-sectional properties are the same, the moment of inertia about axis 2 (I 2 ) and the moment of inertia about axis 3 (I 3 ) must be entered differently.

Enter Cross-Sectional Properties Appropriate for Beam Orientations

The following table shows where the K-node occurs for various surface numbers. The first choice location is where the K-node is created provided the I-, J-, and K-nodes form a plane. If the beam element is colinear with the K-node, then a unique plane cannot be formed. In this case, the second choice location is used for that element.

Correlation of Surface Number and K-Node (Axis 2 Orientation)

|

Surface Number |

First Choice K-node Location |

Second Choice K-node Location |

|

1 |

1E14 in +Y |

1E14 in -X |

|

2 |

1E14 in +Z |

1E14 in +Y |

|

3 |

1E14 in +X |

1E14 in +Z |

|

4 |

1E14 in -Y |

1E14 in +X |

|

5 |

1E14 in -Z |

1E14 in -Y |

|

6 |

1E14 in -X |

1E14 in -Z |

You can change the surface number, hence the default orientation. Select the beam elements use the Selection Select

Select Lines command and right-click in the display area. Select the Edit Attributes command and change the value in the Surface: field.

Lines command and right-click in the display area. Select the Edit Attributes command and change the value in the Surface: field.

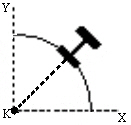

In some situations, a global K-node location may not be suitable. In this case, select the beam elements in the FEA Editor environment using the Selection Select

Select Lines command and right-click in the display area. Select the Beam Orientations

Lines command and right-click in the display area. Select the Beam Orientations New.. command. Type in the X, Y, and Z coordinates of the K-node for these beams. To select a specific node in the model, click the vertex, or enter the vertex ID in the ID field. A blue circle appears at the specified coordinate. The following image shows an example of a beam orientation that needs the origin defined as the k-node.

New.. command. Type in the X, Y, and Z coordinates of the K-node for these beams. To select a specific node in the model, click the vertex, or enter the vertex ID in the ID field. A blue circle appears at the specified coordinate. The following image shows an example of a beam orientation that needs the origin defined as the k-node.

Skewed Beam Orientation

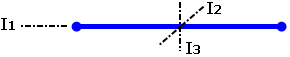

The direction of axis 1 can be reversed in the FEA Editor by selecting the elements to change (Selection Select

Select Lines), right-clicking, and choosing Beam Orientations

Lines), right-clicking, and choosing Beam Orientations Invert I and J Nodes. This ability is useful for loads that depend on the I and J nodes and for controlling the direction of axis 3. (Recall that axis 3 is formed from the right-hand rule of axes 1 and 2.) If any of the selected elements have a load that depends on the I/J orientation, you choose whether or not to reverse the loads. Since the I and J nodes are being swapped, choose Yes to reverse the input for the load and maintain the current graphical display. The I and J nodes are inverted, and the I/J end with the load is also inverted. Choose No to keep the original input, so an end release for node I switches to the opposite end of the element since the position of the I node is changed.

Invert I and J Nodes. This ability is useful for loads that depend on the I and J nodes and for controlling the direction of axis 3. (Recall that axis 3 is formed from the right-hand rule of axes 1 and 2.) If any of the selected elements have a load that depends on the I/J orientation, you choose whether or not to reverse the loads. Since the I and J nodes are being swapped, choose Yes to reverse the input for the load and maintain the current graphical display. The I and J nodes are inverted, and the I/J end with the load is also inverted. Choose No to keep the original input, so an end release for node I switches to the opposite end of the element since the position of the I node is changed.

The orientation of the elements can be displayed in the FEA Editor environment using the View  Visibility

Visibility  Object Visibility

Object Visibility Element Axis commands. The orientation can also be checked in the Results environment using the Results Options

Element Axis commands. The orientation can also be checked in the Results environment using the Results Options View

View  Element Orientations command. Choose to show the Axis 1, Axis 2, and/or Axis 3 using red, green, and blue arrows, respectively. See the following figure.

Element Orientations command. Choose to show the Axis 1, Axis 2, and/or Axis 3 using red, green, and blue arrows, respectively. See the following figure.

Beam Orientation Symbol (different arrows are used for each axis.)

Specify Cross-Sectional Properties of Beam Elements

The Sectional Properties table in the Cross-Section tab of the Element Definition dialog box is used to define the cross-sectional properties for each layer in the beam element part. A separate row appears in the table for each layer in the part. The sectional property columns are:

- A: Specify the cross-sectional area in this column. It is the area of the beam resisting the axial force (δ=FxL/(AxE)). This area must be greater than 0.0.

- J1: Specify the torsional resistance in this column. The torsional resistance is the area moment of inertia resisting the torsional moment M1. The angle of twist within an element is calculated by ϑ=M1xL/(J1xG) where L is the length and G is the shear modulus. For most cross-sections, the torsional resistance is much less than the polar moment of inertia. (For a circular section, J1 equals the polar moment of inertia.) The torsional resistance must be greater than 0.0.

- I2: Specify the area moment of inertia about the local 2 axis in this column. (It is also referred to as I 2-2 .) The local 2 axis passes through the neutral axis of the cross section and is in the plane formed by the element and the k-node. (See previous paragraph.). The moment of inertia must be greater than 0.0.

- I3: Specify the area moment of inertia about the local 3 axis in this column. (It is also referred to as I 3-3 .) The local 3 axis passes through the neutral axis of the cross section and forms the right-hand rule with the element (axis 1) and axis 2. The moment of inertia must be greater than 0.0.

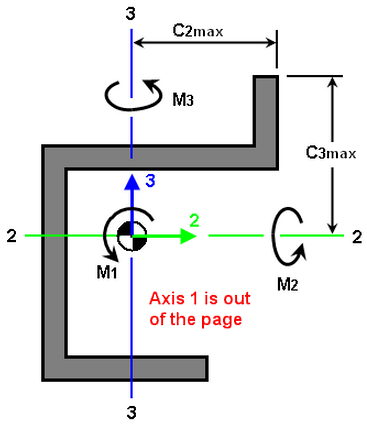

- S2: Specify the section modulus about the local 2 axis in this column. The section modulus is calculated from S2=I2/C3max, where C3max is measured parallel to the 3 axis from the neutral axis to the furthermost point on the cross section. This value is not required but is necessary for the bending stress calculation about axis 2 (=M2/S2). If this value is 0.0, the bending stress about the local 2 axis is set to 0.

- S3: Specify the section modulus about the local 3 axis in this column. The section modulus is calculated from S3=I3/C2max, where C2max is measured parallel to the 2 axis from the neutral axis to the furthermost point on the cross section. This value is not required but is necessary for the bending stress calculation about axis 3 (=M3/S3). If this value is 0.0, the bending stress about the local 3 axis is set to 0.

- Sa2: Specify the shear area parallel to the local 2 axis. The shear area is the effective beam cross-sectional area resisting the shear force R2 (shear force parallel to axis 2). If the shear area is 0.0, the shear deflection in the local 2 direction is ignored (usually a safe assumption). The shear area correction is only needed if the beam width is comparable to the beam length.

- Sa3: Specify the shear area parallel to the local 3 axis. The shear area is the effective beam cross-sectional area resisting the shear force R3 (shear force parallel to axis 3). If the shear area is 0.0, the shear deflection in the local 3 direction is ignored (usually a safe assumption). The shear area correction is only needed if the beam width is comparable to the beam length. Note: Hand calculations for the deflection of beams rarely include the effects due to shear within a beam. For example, the well-known equations for the maximum deflection for a cantilever beam and simply supported beam due to a point load (FL 3 /(3EI) and FL 3 /(48EI), respectively) only consider the bending effects. If shear effects are included in the finite element analysis by entering values for Sa2 and Sa3, the calculated displacements can be higher than the hand calculations.

If you know the dimensions of the cross-section instead of the properties, you can use the cross-section libraries to determine the necessary values.

Use Cross-Section Libraries

To use the cross-section libraries, first select the layer for which you want to define the cross-sectional properties. After the layer is selected, click the Cross-Section Libraries button.

How to Select a Cross Section from an Existing Library

- Select the library in the Section database: drop-down menu. Multiple versions of the AISC Library are provided with the software. (Note: The AISC library is set so that the IYY from the AISC manual corresponds to I2 in the software.)

- Select the cross section type using the Section type pull down. The types available for each database are given in the following table.

- Select the cross section name in the Section name: section. You can search for a name by typing a string in the field above the list.

- Review the values in the Cross-sectional properties section. If they are acceptable, click OK. The AISC library may not have all the values needed to perform an analysis.

|

AISC 2005 & 2001 |

AISC Rev 9 |

AISC Rev 8 & 7 |

Shape |

|

W |

W Type |

W Type |

W shapes |

|

M |

M Type |

M Type |

M shapes |

|

S |

S Type |

S Type |

S shapes |

|

HP |

HP Type |

HP Type |

HP shapes |

|

C |

C Type |

C Type |

Channels - American Standard |

|

MC |

M Type (MC) |

M Type (MC) |

Channels - Miscellaneous |

|

L |

L Type |

L Type |

Angles - equal legs |

|

L |

L Type |

UL Type |

Angles - unequal legs |

|

WT |

WT Type |

WT Type |

Structural tees cut from W shapes |

|

MT |

M Type (MT) |

M Type (MT) |

Structural tees cut from M shapes |

|

ST |

S Type (ST) |

S Type (ST) |

Structural tees cut from S shapes |

|

2L |

2L Type |

DL Type |

Double angles - equal legs* |

|

2L (LLBB on end of name) |

2L Type (first dimension is back-to-back dimension) |

UD Type (UDL) |

Double angles - unequal legs* (long legs back to back) |

|

2L (SLBB on end of name) |

2L Type (first dimension is back-to-back dimension) |

UD Type |

Double angles - unequal legs* (short legs back to back) |

|

Pipe (schedule on end of name) |

P Type |

S Type (SP, schedule on end of name) |

Pipe - STD standard weight |

|

Pipe (schedule on end of name) |

P Type (PX) |

S Type (SP, schedule on end of name) |

Pipe - XS extra strong |

|

Pipe (schedule on end of name) |

P Type (PXX) |

S Type (SP, schedule on end of name) |

Pipe - XXS double extra strong |

|

HSS |

TS Type |

RTU |

Structural tubing - rectangular |

|

HSS |

TS Type |

S Type (STU) |

Structural tubing - square |

|

AISC Library Section Type - If the section name differs from the type, it is noted in parentheses ( ). |

|||

| *When four numbers are given, the fourth number is the distance between the legs of the angle. For example, the 2L8x4x7/8x3/4LLBB are double 8x4 angles, 7/8 inch thick legs with the long legs back to back and separated by 3/4 inch. | |||

- To visualize the beam cross section in the Results environment, the cross section must be chosen from the AISC 2001 or AISC 2005 database.

- The AISC 2005 database corresponds to the data in the Thirteenth Edition of the AISC Steel Construction Manual.

How to Create a New Library:

- Click the Add button below the Section database: drop-down menu..

- Enter a name for the library and click the OK button.

- Enter a name for the database file and click the Save button. The new library appears in the Section database: drop-down menu.

How to Add a Cross Section to a Library:

- Select the library in the Section database: drop-down menu. You can only add a cross section to a library created by a user.

- Click the Add button below the Section name: section and click the OK button. The section name appears in the list in the Section name: section.

- Select the new section and enter the values in the Cross-sectional properties section.

- Click the Save button.

How to Define the Dimensions of a Common Cross-Section:

- With a cross section created by a user selected, change the pull-down menu in the upper-right corner from the User-Defined option to the geometry type.

- Enter the appropriate dimensions shown at the right side of the dialog box.

- Click the Save button.

Other Beam Element Parameters

In addition to the cross-sectional properties, the only other parameter for beam elements is the stress free reference temperature. It is specified in Stress Free Reference Temperature field in the Thermal tab of the Element Definition dialog box. This value is used as the reference temperature to calculate element-based loads associated with constraint of thermal growth using the average of the nodal temperatures. The value you enter in the Default nodal temperature field in the Analysis Parameters dialog box determines the global temperatures on nodes that have no specified temperature.

Basic Steps to Use Beam Elements

- Be sure that a unit system is defined.

- Be sure that the model is using a structural analysis type.

- Right-click the Element Type heading for the part that you want to be beam elements..

- Select the Beam command.

- Right-click the Element Definition heading.

- Select the Edit Element Definition command.

- In the Cross Section tab, enter in the proper cross sectional properties for each layer of beams. To use saved properties, press the Cross-Section Libraries button.

- Once your sectional properties are entered, click OK.