The Damper object consists of a base, a main housing, and a piston, with an optional boot. The piston slides within the main housing, providing different heights. The overall height can be affected by binding objects in the same way as the Spring object.

Procedures

To create a damper:

- Drag and release to specify the diameter.

- Move the mouse and click to specify the overall height of the damper.

To use a damper in a dynamics simulation:

- Bind two objects to the ends of the damper, and choose Bound to Object Pivots in the End Point Method group box at the top of the command panel.

- In the dynamics simulation, add the damper to the Object List. (The damper itself is not adjusted in the dynamics simulation, so all of the dynamics parameters will be disabled for the damper object.)

- Include at least one of the bound objects or a parent of one of the bound objects in the simulation. For example, you can bind two dummy objects to the ends of a damper, and one of the dummies can be the child of an object that’s included in the simulation. In this case, the dummy itself does not need to be in the simulation. Note: Damper is an "ideal" object with no mass. While it can be used in dynamics simulations, it cannot participate directly in collisions or effects. As a result, when you assign a damper object to a dynamics simulation, and then view it in the Edit Object dialog, all of the parameter settings are disabled.

The following must be in place to use the damper forces in a dynamics simulation:

Interface

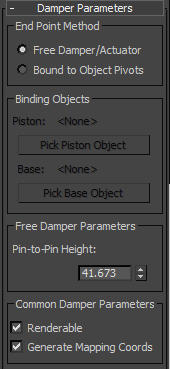

End Point Method group

- Free Damper/Actuator

-

Choose this when using the damper as a simple object that’s not bound to others or used in a dynamics simulation.

- Bound to Object Pivots

-

Choose this option when binding the damper to two objects, using the buttons described next.

Binding Objects group

Use these controls to pick the objects to which the damper is bound. To complete the binding, you must select two binding objects, and then click Bound to Object Pivots.

- Piston (label)

-

Displays the name of the object bound to the piston of the damper.

- Pick Piston Object

-

Click this button and then select the object to be bound to the piston of the damper.

- Base (label)

-

Displays the name of the object bound to the base of the damper.

- Pick Base Object

-

Click this button and then select the object to be bound to the base of the damper.

Free Damper Parameters group

- Pin-to-Pin Height

-

Use this field/spinner to specify the distance between the bottom center of the base and the top center of the piston when the damper is not bound.

Common Damper Parameters group

- Renderable

-

When on, the object appears in the rendering; when off, the object does not appear.

Material IDs are assigned to the damper object as follows:

1: Base

2: Main housing

3: Piston

4: Boot Stop (appears only if you enable Boot Parameters)

5: Boot (appears only if you enable Boot Parameters)

- Generate Mapping Coords

-

Sets up the required coordinates for applying mapped materials to the object. Default=on.

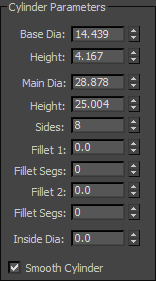

Cylinder Parameters group

Provides parameters for the base and main cylinder of the damper.

- Base Dia(meter)

-

The diameter of the base, or "mount" of the damper.

- Height

-

The height of the base.

- Main Dia

-

The diameter of the main housing of the damper.

- Height

-

The height of the main housing.

- Sides

-

The number of sides of both the base and the main housing.

- Fillet 1

-

The size of the fillet on the lower edge of the main housing.

- Fillet Segs

-

The number of segments for Fillet 1. The higher this setting, the rounder the fillet profile appears.

- Fillet 2

-

The size of the fillet on the upper edge of the main housing.

- Fillet Segs

-

The number of segments for Fillet 2. The higher this setting, the rounder the fillet profile appears.

- Inside Dia(meter)

-

Specifies the inside diameter of the main housing, which is actually a tube rather than a cylinder.

- Smooth Cylinder

-

When on, smoothing is applied to both the base and the main housing.

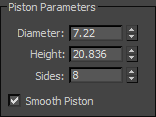

Piston Parameters group

Provides parameters for the piston of the damper.

- Diameter

-

The diameter of the piston.

- Height

-

The height of the piston.

- Sides

-

The number of sides in the piston.

- Smooth Piston

-

When on, smoothing is applied to the piston.

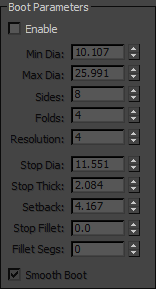

Boot Parameters group

The boot is an optional component of the damper that’s similar to the rubber "accordion" boot found on various types of dampers, such as shock absorbers. The boot acts like a bound dynamic object, in that one of its ends is bound to the main housing, while the other is bound to the piston. Thus, as the piston moves within the housing, the boot expands and contracts to follow.

- Enable

-

Turn this on to add the boot to the damper.

- Min Dia

-

The minimum diameter of the boot. This and the next parameter affect the depth of the accordion folds in the boot.

- Max Dia

-

The maximum diameter of the boot.

- Sides

-

The number of sides making up the boot.

- Folds

-

The number of accordion folds (bulges) along the height of the boot.

- Resolution

-

The number of segments in each fold.

- Stop Dia

-

The diameter of the stop, which is the ring at the top of the boot.

- Stop Thick

-

The thickness (height) of the stop ring.

- Setback

-

The distance of the stop ring from the top of the piston.

- Stop Fillet

-

The size of the fillet on the upper edge of the stop ring.

- Fillet Segs

-

The number of segments the stop fillet. The higher this setting, the rounder the fillet profile appears.

- Smooth Boot

-

When on, smoothing is applied to the boot.