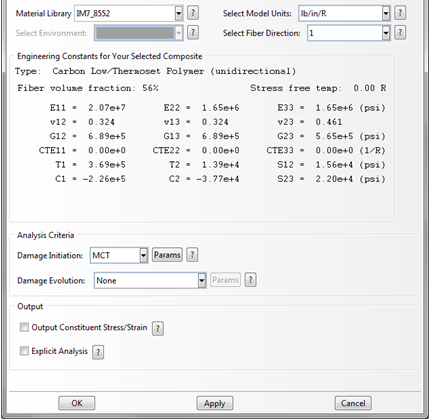

The Create Composite Material plug-in is the central interface between you and Simulation Composite Analysis.

It allows you to choose from a variety of material and analysis options including the following:

- Selection of a composite material to use in the analysis (Simulation Composite Analysis compatible material definitions must be created outside of Abaqus/CAE using Composite Material Manager)

- The choice of four unit systems

- Selection of the principle material direction

- Creating additional output variables that provide fiber and matrix constituent stresses and strains

- Inclusion of progressive failure in the analysis. When this option is used, Simulation Composite Analysis will degrade (reduce) the material properties when failure in the matrix or fiber is detected. If this feature is inactive (the focus of this tutorial), the material retains its original (undamaged) properties when failure is detected.

- Inclusion of pre failure nonlinearity

- Setting the matrix and fiber constituent stiffness post-failure degradation ratios (traditional) or degradation energies (energy based degradation)

Using these options, you can tailor the analysis to the requirements of the problem. For a detailed discussion of the options available, refer to the Simulation Composite Analysis User's Guide.

In the following steps, a user-material is defined using the Create Composite Material plug-in.

- Select from the main toolbar.

- From the Material Library list, select the material IM7_8552.

Note: The unit system dependent Engineering Constants specific to this material are listed in the dialog box for you to review.

- Since this model uses inches and pounds as base units, select lb/in/R from the Select Model Units list. There are 4 unit systems to choose from. The default unit system is N/m/K.

- Select 1 as the fiber direction.

2 can also be used as the fiber direction, but it would require a different composite layup orientation than the 1 direction. As a general rule, it is recommended that 1 be used as the fiber direction to maintain consistency from model to model. On occasion, however, it will not be possible to create an orientation in Abaqus that allows for the 1 direction to be the fiber direction due to the combination of complex model geometry and section orientation limitations. In such cases, it may be necessary to use the 2 direction as the fiber direction.

- In the Damage Evolution menu, select None. With progressive failure deactivated, the stiffness of the elements remains unchanged throughout the analysis. In contrast, when Instantaneous or Energy-Based damage evolution routines are used, the stiffnesses of the elements are reduced after failure has been predicted by the failure criterion.

- The plug-in should appear as shown below.

- Click OK.

After completing steps 1-7, a user material is created in the Materials container  in the Material Tree. This material is used to define the composite layup for the plate.

in the Material Tree. This material is used to define the composite layup for the plate.