View the steps necessary to create a composite material for use with Simulation Composite Analysis.

Composite Material Manager is a standalone application which comes standard as part of the installation module. It is designed to take known composite properties and optimize the constituent properties so a consistent set of properties are generated when predicting the response of the constituents to a fatigue load imposed on a composite.

- To begin the optimization process, open Composite Material Manager.

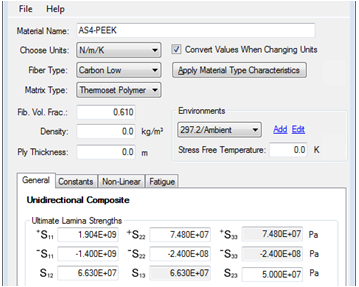

- Specify a unidirectional material under .

- Populate the GUI as shown below .

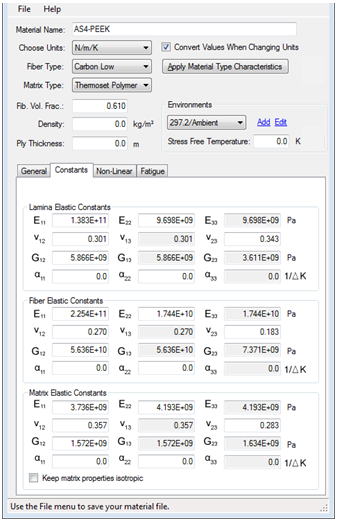

- Now switch to the Constants tab within the GUI and enter the elastic constants as shown below

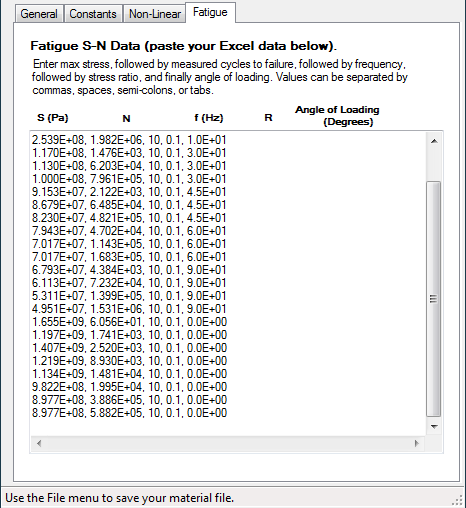

- Switch to the Fatigue tab within the GUI and enter the S-N data as shown below. You can copy and paste the values from the tables seen previously.

- Now that the material properties have been defined, save the newly created material by selecting . Click Yes to allow Composite Material Manager to optimize the constituent properties. After optimization, you will be notified of a successful save.