- Click .

- Click .

- Copy and paste the data below [1] into the Add Non-Linear Material dialog.

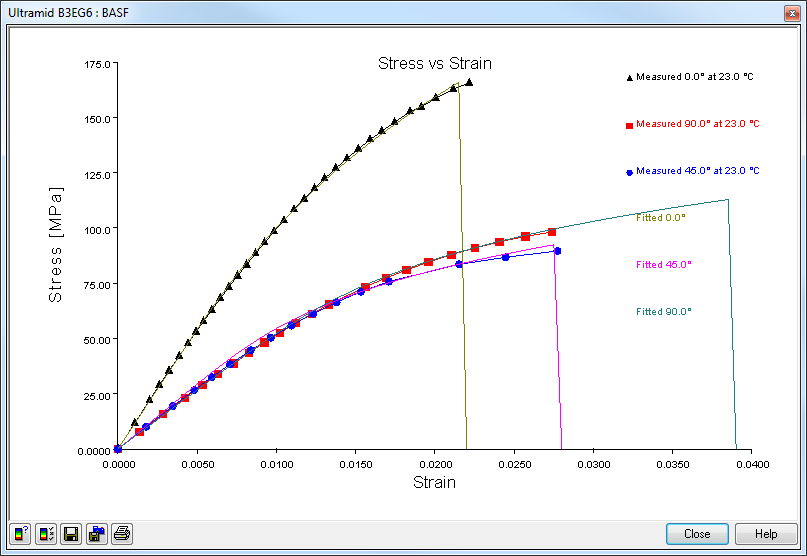

Stress (MPa) Strain (mm/mm) Angle (°) Temp (°C) 0 0 0 23 11.7945 0.001064 0 23 21.99841 0.001993 0 23 28.92476 0.002614 0 23 35.32054 0.003215 0 23 42.08288 0.00386 0 23 47.8012 0.004422 0 23 52.97319 0.004923 0 23 57.68847 0.005393 0 23 62.89662 0.005915 0 23 68.09287 0.006454 0 23 73.18886 0.006993 0 23 78.25729 0.00754 0 23 83.31084 0.008099 0 23 88.35387 0.008671 0 23 93.36761 0.009255 0 23 98.34512 0.009853 0 23 103.3201 0.010469 0 23 108.225 0.011098 0 23 113.0714 0.011742 0 23 117.8402 0.012401 0 23 122.2841 0.013043 0 23 126.9724 0.013746 0 23 131.4255 0.014451 0 23 135.5258 0.015149 0 23 139.8948 0.015912 0 23 143.684 0.016654 0 23 147.7255 0.017437 0 23 152.5762 0.018432 0 23 154.6777 0.019134 0 23 158.5864 0.020048 0 23 162.7148 0.021149 0 23 165.4935 0.022157 0 23 0 0 90 23 7.579338 0.001347 90 23 15.73027 0.002852 90 23 23.09458 0.004233 90 23 28.86905 0.00534 90 23 33.84159 0.006318 90 23 38.72688 0.007302 90 23 43.52814 0.008281 90 23 48.12393 0.009248 90 23 52.5562 0.010217 90 23 56.98764 0.011227 90 23 61.1457 0.012229 90 23 65.3673 0.013311 90 23 73.38244 0.015615 90 23 77.26465 0.016885 90 23 80.99502 0.018215 90 23 84.51849 0.019595 90 23 87.8606 0.021032 90 23 90.93739 0.022525 90 23 93.7159 0.024077 90 23 96.14697 0.025705 90 23 98.17173 0.027405 90 23 0 0 45 23 10.12003 0.001778 45 23 19.39352 0.003451 45 23 26.6503 0.004805 45 23 32.52005 0.005917 45 23 38.24984 0.007064 45 23 44.60503 0.008373 45 23 50.33386 0.00963 45 23 55.86263 0.010939 45 23 61.19571 0.012314 45 23 66.37415 0.013788 45 23 71.13265 0.015326 45 23 75.74393 0.017093 45 23 83.50243 0.021532 45 23 86.71873 0.024462 45 23 89.52131 0.027721 45 23 - Make sure the appropriate units are selected and click Plot Profile to view the non-linear stress-strain data.

- Click Close and click Done.

- Review the mechanical properties of the material by clicking .

- Navigate to the Mechanical Models tab to review the calculated Ramberg-Osgood parameters. Click OK.

Note: Now that you have learned to use Advanced Material Exchange to add non-linear stress-strain data to your model, you may wish to use a personal database file to store the Ramberg-Osgood parameters for future use.

To create a personal database file after you have added the non-linear stress and strain data:

- Click .

- Save the file to your Moldflow Synergy materials directory (usually C:\Program Files\Autodesk\Simulation Moldflow Synergy 2015\data\udb).

- Open a Moldflow Insight model and select the material ().

- Locate the Ultramid B3EG6 manufacturer and choose the appropriate trade name for the .udb file you just saved.

Now this material has the Ramberg-Osgood parameters stored, so when you import your next model into Advanced Material Exchange you won't need to add the non-linear stress-strain data.