The size and complexity of a part along with the number and position of injection locations will determine the mold cost.

Because plastic injection molded parts can have a large range of size and complexity, the Mold cost indicator is based on a single cavity mold of average size and complexity.

To view the mold cost information, click . The Alerts panel on the same panel will define any mold cost alerts.

Click on the Mold cost icon from either the Alert  or Information

or Information  tab. A dialog appears displaying the mold cost rating and the basis of that rating.

tab. A dialog appears displaying the mold cost rating and the basis of that rating.

Mold cost information

The mold cost is based on the size and complexity of an average single cavity mold.

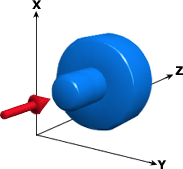

To determine the approximate mold size, the size of the part is examined. As parts come in a variety of shapes the mold cost is based on the area of the part when projected onto the X-Y plane multiplied by maximum height of the part in the Z direction.

The Mold cost is determined based on the following parameters

- Part's height

- The size of the part when measured in the Z direction.

- Part's projected area

- The area of the part when projected onto the X-Y plane.

- Part's complexity

- Geometric features of the plastic part such as the extent of undercuts, and the number and location of injection locations contribute to the cost of manufacturing the metal mold.