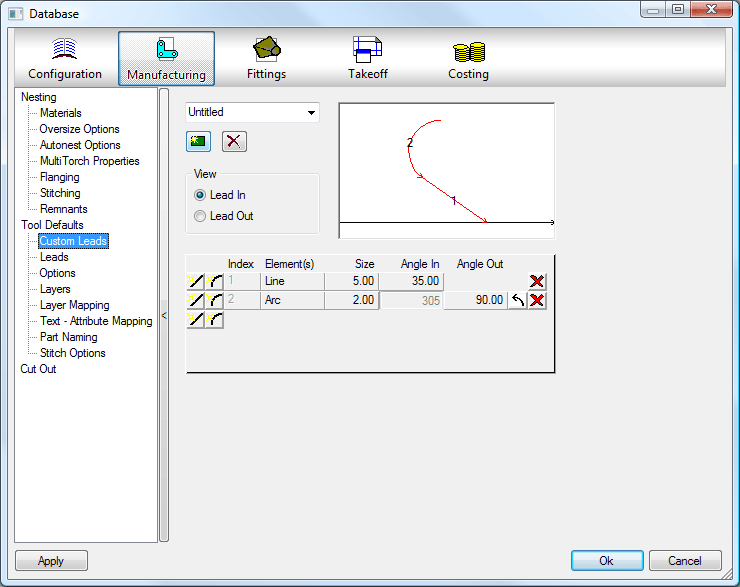

Custom leads are used to create lead styles that are composed of more than one element. As can be seen in the example below, the lead might have to be custom if the complexity of the part demands that the lead in or lead out avoids some other area on the part. Click File  Setup

Setup  Database

Database  Manufacturing and select the Custom Leads tab or select the Database icon from the Utility Bar.

Manufacturing and select the Custom Leads tab or select the Database icon from the Utility Bar.

Custom leads can also be used to improve overall cut quality or can be used as a 'key locking' device to minimise plate distortion. The View toggle changes the way the lead is seen. The lead can still be assigned to a lead In or out independently of this switch.

Creates a new custom lead. Enter a name for the lead in the designation box.

Creates a new custom lead. Enter a name for the lead in the designation box.  Deletes the currently selected custom lead.

Deletes the currently selected custom lead.

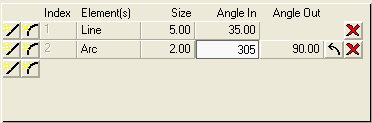

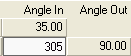

Custom leads are defined by a series of line and arc segments. The line elements are defined by specifying a size and angle for the lead. Arc elements are defined by specifying a size (radius) and the start / end angles of the arc.

The length of the lead section is set here. Each section can be of a different length.

The angle always works with zero pointing to the right. To change from clockwise to anticlockwise, use the  icon. The

icon. The  icon deletes the selected lead section.

icon deletes the selected lead section.