There are four holes in the part; one is clear and three are threaded. Begin by drilling the three threaded holes with a 4.3 mm drill.

- On the ribbon, click

CAM tab

Drilling panel

Drilling panel

Drill

Drill

.

.

Tool tab

Tool tab

- On the Tool tab, click the

button.

button. - From the Sample Libraries > Tutorial tool library, select tool #34 - Ø4.3 mm drill.

- Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Geometry tab

Geometry tab

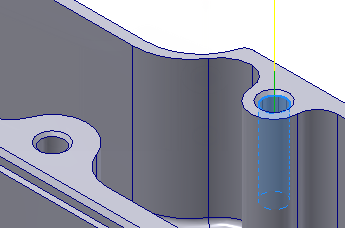

- Click the Geometry tab. Ensure that Selected faces is selected from the Hole mode: drop-down menu and that the Hole faces selection button is active.

- Select the cylindrical face of one of the three 4 mm holes.

- Enable the Select same diameter check box.

Notice that the two other 4 mm holes are selected.

Depending on the selection, you may want to activate the Optimize order check box. The optimization reorders the holes to make the linking distance as short as possible.

Activating the Order by depth check box keeps holes with the same depth and plane together. Doing so may reduce the number of cycles in the output, but may not result in the shortest toolpath, even if Optimize order is enabled.

Heights tab

Heights tab

For a drilling operation, the Heights tab controls the heights of each hole, and the heights used when moving between the holes. Because the holes are chamfered, the actual cylinders start a bit lower. This can be adjusted by making the top start from the top of stock instead.

- Click the Heights tab.

- From the Top Height drop-down menu, select Stock top.

Cycle tab

Cycle tab

- Click the Cycle tab.

- Select Chip breaking - partial retract from the Cycle type: drop-down menu.

- Change Pecking depth to: 2.5 mm

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the drilling toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the drilling toolpath.

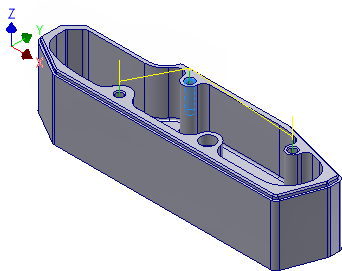

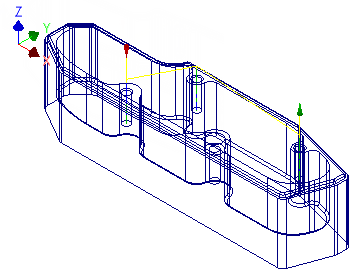

The calculated toolpath should look like this:

Appearance panel

Appearance panel

Wireframe

Wireframe

from the Visual Style drop-down.

from the Visual Style drop-down. Continue to To Tap Holes...