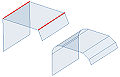

Use a construction surface as a termination face for other features, or as a split tool to create a multi-body part.

Construction surfaces provide ways to describe shapes when creating extrude, revolve, sweep, and thicken parts. For each of these features, you can create a surface instead of a cut, join, or intersection. Specific requirements for creating a surface depend on the feature command you use.

You use an open or closed profile to create a surface. To create one or more features, select the construction surface when a termination plane is required, or as the cutting line to split a part. You can use multiple construction surfaces as the beginning and ending termination planes.

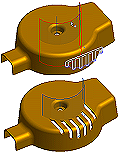

In the part environment, you can use the Stitch command to stitch several edge-matched surfaces together to create a quilt. Unlike the Stitch command in the construction environment, this operation is parametric; changes to the parent surfaces update the quilted surface.

Surface edges must be adjacent to stitch successfully. The stitch command has a tolerance control that provides an upper limit and helps to determine which edges to stitch.

Features do not consume surfaces. In the browser, a surface displays as a suffix to the feature command used to create it (for example, ExtrusionSrf1, SweepSrf1).

Appearance and visibility of surface

In the Application Options dialog box, Part tab, in Construction, you can change the appearance of a surface from translucent to opaque.

By default, before the option is set, surfaces are translucent, like a work plane. To change surface appearance, in the browser, right-click the surface and select Translucent. Select or clear the check mark to switch on and off opacity.

After you use a surface, you can right-click it in the browser or graphics window, and turn off its visibility.

Modification of profile shape for surface

You can use Fillet and Chamfer commands to modify sharp edges of surfaces.

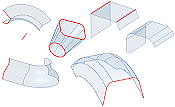

Shapes for surfaces from feature commands

- A revolved surface created from a sketched line rotated around an axis.

- A lofted surface created from two closed profiles.

- Extruded surfaces created from line segments extruded a specific distance. One uses fillets to round corners.

- A swept surface created by a profile containing lines and arcs swept along an arc.

- A revolved surface created by a spline rotated around an axis.