Use Corner Seam Rip on part models that you convert to sheet metal models.

The thickness for converted part models is required to be uniform, and equal to the material thickness defined in the active sheet metal style.

Workflow to open an edge between faces that you later use to flatten the converted part model

- Use Corner Seam Rip.

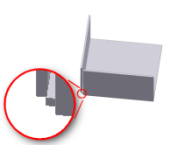

The resulting open corner typically leaves material that must be removed.

- Create a sketch, and manually remove the material using a Cut.

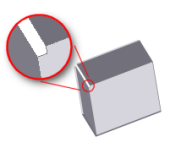

- After the cut operation, apply Bend on the inside edges of what you would model as flanges.

- After you rip and clean up all corners, and manually apply bends, you can flatten your model.