Defines the parameters for all aspects of a corner in a sheet metal feature.

Overrides default parameters in the Sheet Metal Styles dialog box that define how corners are relieved when a folded model is unfolded. Change these parameters for individual features using the Corner Options tab.

- Access

- In the Contour Flange, Flange, or Corner Seam dialog box, click the Corner tab.

Note: Not all options described are available or valid for each feature that shares this tab.

- Defines the Default corner relief shape when 2 bends intersect

-

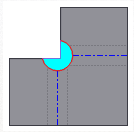

- Round

- A circular cut out centered on the intersection of the bend lines.

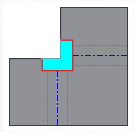

- Square

- A square cut out centered on the intersection of the bend lines.

- Tear

- Extends the flange edges to their intersection. No relief, which allows material failure (tearing) across the bend zone in the folded model.

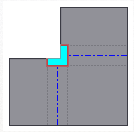

- Trim to Bend

- A polygonal cut out bounded by the bending zone lines.

- Linear Weld

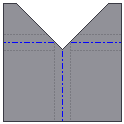

- A V-shaped cut out defined from the intersection of the inner bend zone lines to the outer bend zone intersection of the line with the flange edges. Minimum relief allows a subsequent weld operation to close the corner.

- Arc Weld

- Curves tangent to the flange edges along the outside edge of the bend zone which converge to a flat gap equal to the Miter Gap value. A gap between the flanges that is equidistant along the length of the relief is suitable for subsequent arc welding.

- Round

- Defines the Default corner relief to display in the flat pattern when three bends intersect

-

Note: The folded model does not display the selected relief option.

- No Replacement

- Does not replace the geometry as modeled in the flat pattern

- Intersection

- Extends and intersects the flange edges.

- Full Round

- Extends the flange edges to their intersection, and then places a fillet tangent to the bend zone tangency lines. Radius are likely larger than what is produced using the Round with Radius option.

- Round with Radius

- Extends the flange edges to their intersection, and then places a tangent fillet of the size specified. Radius is likely smaller than what is produced by the Full Round option

- No Replacement

- Relief Size

- Controls the size of the Corner Relief of the selected feature from the default, as defined in the Sheet Metal Style, using the named parameter: CornerReliefSize.

- Apply Auto-Mitering

- Automatically extends material between adjacent flange edges during creation or edit of at least two flange edges during a single operation where bend angle is greater than 90 degrees. Available on Flange and Contour Flange dialog box (not available on Corner tab of Corner Seam dialog box).

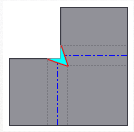

- Apply Auto-Mitering turned on.

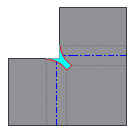

- Apply Auto-Mitering turned off.

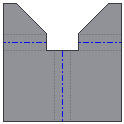

- Apply Auto-Mitering turned on.

- Miter Gap

- When the Auto-Miter is turned on, you can enter a value to change the size of an automatically applied gap between flanges. The value displayed defaults to the system named parameter GapSize, which is defined in the Sheet Metal Style.

- 2 Bend/3 Bend Corner

- Indicates the type of corner relief to apply to the selected geometry. Available only when a choice must be made between the type of corner being specified. When inactive, they indicate the type of corner selected.