Ideally, the placement and extent of gas channels should be controlled by suitable modifications to the part geometry.

In cases where this does not provide sufficient control, overflow wells can be used to increase gas penetration, or direct the gas into specific areas of the part.

An overflow well is a secondary cavity into which the gas can displace polymer and thereby penetrate further into the part. Overflow wells provide paths of least resistance along which the gas will preferentially travel. Further control over gas flow can be achieved by opening and closing the overflow wells at specific times by means of valve gates.

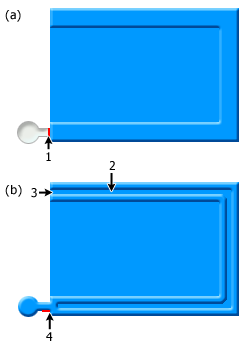

The following figure illustrates the typical application of overflow wells in gas-assisted injection. The passage to the overflow well is generally closed during the injection phase while the plastic is filling the rest of the cavity, as illustrated in a) below. At the end of polymer injection, there is an optional delay time which allows the polymer over the thin sections to solidify. Immediately before gas injection is triggered, the passage to the overflow well is opened, creating an additional volume to accommodate the resin that is displaced by the incoming gas, as illustrated in b) below. After the part is ejected from the mold, the overflow can be trimmed off if it is undesirable.

Legend:

.1) Control valve closed during polymer injection. 2) Gas penetration. 3) Gas entrance. 4) Control valve open during gas injection.

Overflow wells must be modeled with a defined volume. For Midplane models only, an overflow well with infinite volume can be simulated by setting a venting location at the end node of the overflow well.