Unstable warpage leads to buckling of components. The contribution of each of the three shrinkage variates to the total deflection can no longer be assumed to be linear.

In this case, a so-called sensitivity analysis is used. This functionality is available for Midplane analysis technology only.

The aim of the sensitivity analysis is to determine the change in load factor for a known change in the shrinkage. The load factor indicates at what factor of the actual applied loads, in the case of Shrink analysis these being the loads internal to the part, the part warpage becomes unstable, leading to buckling. A load factor less than one indicates the actual loads are sufficient to result in buckling of the part. A load factor greater than one indicates that the warpage is stable as the onset of buckling has been determined to be at a load magnitude higher than the actual loading.

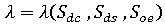

, can be regarded as a function of these components, that is,

, can be regarded as a function of these components, that is,

To solve a warpage problem, we wish to know which component to change to increase the load factor, that is to make the warpage stable. One way of doing this is to take the partial derivatives of  with respect to each component. Unfortunately this cannot be done analytically as there is no known function relating

with respect to each component. Unfortunately this cannot be done analytically as there is no known function relating  to the components. Instead the partial derivatives are approximated.

to the components. Instead the partial derivatives are approximated.

. Now increase one of the shrinkage components by some amount,

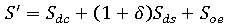

. Now increase one of the shrinkage components by some amount,  say, to give a new total shrinkage S'. For example, if we increase the differential shrinkage component, we would have:

say, to give a new total shrinkage S'. For example, if we increase the differential shrinkage component, we would have:

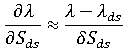

, the derivative of

, the derivative of  with respect to the differential shrinkage component is approximated as follows:

with respect to the differential shrinkage component is approximated as follows:

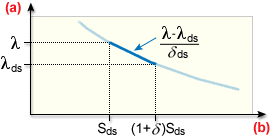

See Load factor as a function of shrinkage

Load factor as a function of shrinkage

.(a) Load Factor, (b) Shrinkage

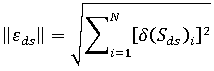

The above holds for one element only. For a real part, each element has a value of  . To cope with this, the elemental changes are combined into a single measure of shrinkage change. The norm of the changes are used in the elemental shrinkages to obtain the single value.

. To cope with this, the elemental changes are combined into a single measure of shrinkage change. The norm of the changes are used in the elemental shrinkages to obtain the single value.

where N is the number of elements in the model.

The value (1 +  ) is called the sensitivity factor which is a program input.

) is called the sensitivity factor which is a program input.

Similarly, the sensitivities of the load factors for differential cooling and orientation effects variates, respectively, are calculated.