Fiber orientation prediction involves determining the spatial distribution of fibers, for each element and as a function of location through the part thickness.

While injection molded fiber-reinforced thermoplastics constitute a major commercial application of short fiber composite materials, the modeling of the process is more complex than in other applications as parts are usually thin and shorter fibers are often used. Other aspects such as the three-dimensional orientation of the fibers and the significant orientation variations across the part also contribute to the complexity of the problem.

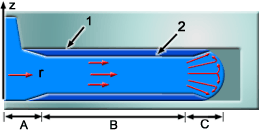

During the filling of an injection molding die, three flow regions normally exist (Flow regions during filling). These regions are:

- A 3D region near the gate (Region A).

- A lubrication region (Region B), where no significant velocities out of the main flow plane exist and where the majority of the flow is contained.

- A fountain flow region at the flow front (Region C).

Flow regions during filling

.(1) Mold wall; (2) Frozen layer.

Of the various mold filling simulations developed, most simplify the governing equations using the assumptions:

-

Most moldings are thin.

-

Flow is approximated to occur in the lubrication region.

During molding, the fiber orientation at a position is controlled by the fluid motion in two different ways:

-

Flow-deduced orientation (a kinematic term).

-

Flow-convected orientation (an advection term).

When modeling this, the accuracies of these separate terms depend on the accuracy of the determined velocity gradient and orientation gradient respectively.

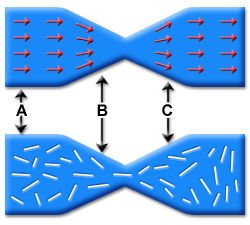

The effect of flow behavior on fiber orientation is complex, but two rules of thumb have been demonstrated (Effect of stretching flows on fiber alignment):

-

Shearing flows tend to align fibers in the direction of flow.

-

Stretching flows tend to align fibers in the direction of stretching. For a center-gated disk, the stretching axis is perpendicular to the radial flow direction.

Effect of stretching flows on fiber alignment

.A = Entrance: Random fibers, B = Converging flow: Flow aligned fibers, C = Diverging flow: Transverse alignment

It has been found that the orientation of fibers in injection molded composites is layered, with a core created by in-plane fiber motion during mold filling.

For a radial flow case (as in a center-gated disk), there is an in-plane stretching flow and the core layer contains fibers aligned in the stretching direction.

For a case where no stretching applies, as for a strip mold, the orientation set by the flow at the gate is simply convected down the flow length with little change, giving:

-

Shell layers on either side of the core, with a flow aligned orientation caused by gapwise shearing.

- Skin layers at the mold surface:

- when thick frozen layers form during filling.

- orientation is set by the fountain flow, at a value between that of the core and shell layers.

The number, thickness and type of layers depending on the location in the part and the part geometry. In addition to the above, it is observed that:

-

Processing conditions and material behavior do affect the orientation.

-

The filling speed is the process parameter that most influences fiber orientation. Faster injection speeds cause thicker core layers and thinner skin layers.

-

The fiber average aspect ratio and concentration also influence the fiber orientation. With increased fiber aspect ratio and concentration, the flow-aligned orientation in the shell layer increases.

There are three factors which must be considered by the analysis program for a fiber-filled material. They are:

-

The general fluid dynamics of the molten polymer.

-

The effects of the molten polymer on the fibers.

-

The inter-fiber interactions.

The general fluid dynamics of the molten polymer is dealt with using Autodesk Simulation Moldflow's regular Fill+Pack analysis algorithm, but the effects of the molten polymer on the fibers and the interaction of the fibers requires the use of an equation of motion for rigid particles in a fluid suspension.