The 3rd user material constant activates or deactivates Helius PFA' progressive failure analysis feature. If the progressive failure feature is activated, Helius PFA will routinely evaluate both the matrix failure criterion and the fiber failure criterion to determine if either constituent material has failed. Each constituent failure criterion is based on the corresponding constituent average stress state. For the purposes of this specific discussion, we assume that pre-failure nonlinearity is de-activated. In the event that one or both of the constituents fail, the stiffness of the failed matrix and fiber are appropriately reduced to the values specified by the 12th and 13th material constants, respectively. Helius PFA then calculates the current composite average stiffness based on the current state (failed, or not failed) of each constituent material.

The value of the third user material constant has different implications depending on the microstructure of the material.

Unidirectional Microstructures: A value of 1 activates the progressive failure analysis feature, while a value of 0 deactivates the progressive failure analysis feature.

Woven Microstructures: A value of 0 deactivates the progressive failure feature. A value of 1 activates the progressive failure feature and uses the matrix and fiber degradation levels from the material data file to calculate the failed material properties. A value of 2 activates the progressive failure feature and uses the matrix and fiber degradations levels specified by the twelfth and thirteenth user material constants to calculate the failed material properties. Selecting a value of 2 for plain weaves will add approximately 45-60 seconds to the pre-processing time per woven material. A value of 1 will not add run-time during pre-processing because the failed material properties (at the matrix and fiber degradation levels specified during material creation in Composite Material Manager) are already stored in the material file.

The progressive failure analysis feature is the foundation component of the product's nonlinear multiscale constitutive relations. The discrete values that can be assumed by SV2 differ depending on the microstructure of the underlying composite and additional forms of material nonlinearity invoked. A comprehensive listing of the allowable discrete values for SV2 is provided in Appendix C. Additionally, a description of each discrete composite damage state is written in the summary file (*.mct) created during the preprocessing phase of the analysis.

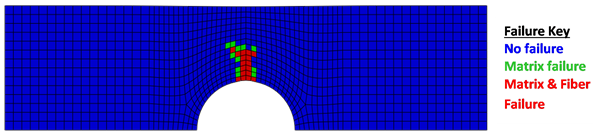

The image below shows a [0°/ ±45°]s unidirectional composite plate that was analyzed using the progressive failure feature. It shows a contour plot of the MCT state variable SV2, representing the composite damage state in the 0° plies. The blue areas represent composite material with unfailed constituents (SV2=1), the green areas represent composite material with a failed matrix constituent (SV2=2), and the red areas represent composite material with matrix and fiber constituents that have failed (SV2=3).

For further information on the progressive failure analysis feature, refer to the Theory Manual.

To summarize, with progressive failure activated, the element stiffness is reduced when damage is predicted. With progressive failure deactivated, the element stiffness remains constant throughout the entire analysis.