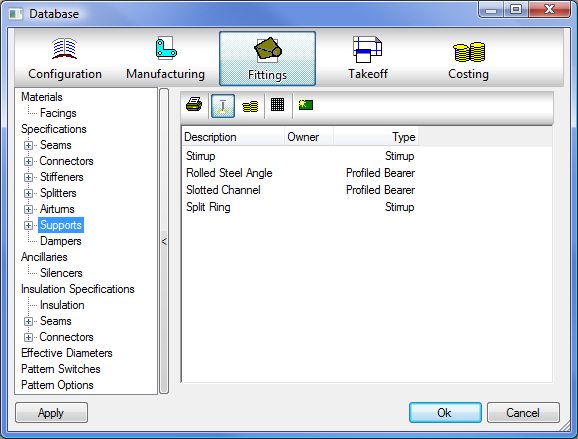

To edit or setup supports, navigate to your Database, click Fittings, then select Supports under Specifications.

There are two sections to the Supports settings: Manufacturing and Estimating. Both are accessed through the top toolbar.

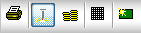

Supports Toolbar

Gives a full print of the current support configuration and assignments.

Gives a full print of the current support configuration and assignments.

The default is the manufacturing view. This lists all the supports in the database and their types allocated.

The default is the manufacturing view. This lists all the supports in the database and their types allocated.

Provides the ability to assign a Labor rate for costing against any fabrication or installation time of the support ancillaries.

Provides the ability to assign a Labor rate for costing against any fabrication or installation time of the support ancillaries.

Filter out Non User Data, allows the filtering of Autodesk-supplied content from the view.

Filter out Non User Data, allows the filtering of Autodesk-supplied content from the view.

Creates a new support type. If an existing support is highlighted when pressing this icon, there will be a prompt to copy the existing supports values.

Creates a new support type. If an existing support is highlighted when pressing this icon, there will be a prompt to copy the existing supports values.

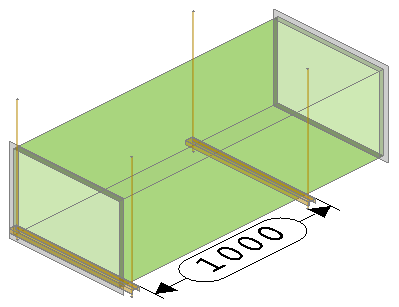

Supports can be applied to Straights or Pipes using Specification. This is so the quantity and type of support can be defined based upon the items dimensions. The supports are dictated by the length of duct or pipe entered against a support spacing requirement in the specification. The value on the spacing field identifies when the supports are to be assigned to the item. Each size of duct or pipe entered can therefore be given a support style so the heavier the duct or pipe is, alternative strengths of supports can be used at varying spacing requirements.

Using item specification, you can assign the type of support against each breakpoint size and additionally enter a spacing value for each instance. The diagram of the Rectangular Straight piece dictates how the spacings are calculated. The first support is always at the zero length, and then based on the length entered, additionally added for each spacing value. The example shows a 1000mm spacing on a 1500mm duct length therefore 2 supports will be included into the Straight Rate.

The other methods of using supports are through individual item files and using the Takeoff as Cut In procedure from the service button, or using Design Line Support Specifications for automatic population into the drawing.

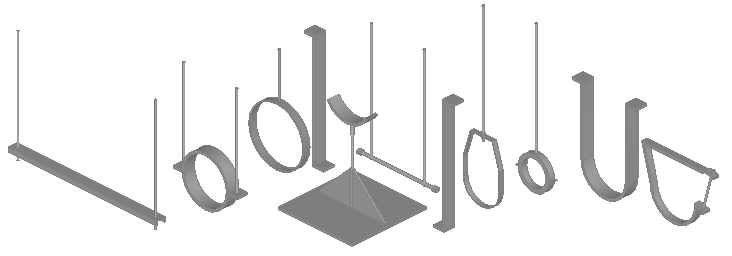

The support item file (CID 838) has a number of support options which allow you to choose from the various styles of the item for drawing. The following illustration shows some of these support style options as they are displayed in a 3D view.

For assignment of supports, we recommend using one method, either the Item Specification or Service Support Specification. This reduces the risk of potentially duplicating the supports in the job or model.

Supports can be quantified and costed if using our estimating solution providing supplier prices/codes or installation times for the project.

Important: There are two methods for automatic assignment of supports. For estimating support lengths and ancillary quantities (Estimating solution), a decision is required as to which method is to be used in the configuration. Only using one of these methods is recommended else duplication of support could occur.

1. The first method to decide upon is whether the Supports are to be priced inclusive in the items rate under the Material breakdown itself, this method would be without the need to draw them visually in the view. Commonly used with Estimators who, for analysis and quantifying only purposes, would need to assign in the Specification, a Support build up. Please view the Supports - Example for more information on this method.

OR

2. The second method would require Supports to be disabled through Item Specifications and in place be allocated though Service Support Specifications. This method of hangers allows each hanger to be individually entered with their own item rate.