In the RTM (Resin Transfer Molding) and SRIM (Structural Reaction Injection Molding) analyses, resin is forced to flow through a cavity in which reinforcing preform (also called fiber mat) is present.

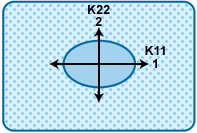

The flow type, characterized by the preform properties, may be isotropic or anisotropic depending on the preform structure. The resistance of a resin to flowing through the preform also depends on the resin properties and flow rate.

- Porosity and permeability.

- Orientation, if the preform is anisotropic.

Preform porosity

Porosity represents the packing density of the preform in the cavity. Porosity is defined as the ratio of the void volume to the cavity volume, before the cavity is filled with resin. The void volume is equal to the cavity volume minus the volume occupied by the fiber reinforcement.

Preform permeability

Permeability is the ability of a fluid to flow through a porous medium. The greater the permeability, the more easily the fluid flows through the medium. For RTM and SRIM processes, permeability depends on the network structure of the fiber mat.

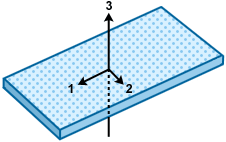

The in-plane and the transverse-to-flow structures of the fiber mat can be different, and can create different resistance to the flow.

Transverse permeability is used to characterize the flow of autoclave composite processing. In-plane permeability is used to determine the flow resistance in RTM or SRIM, since these processes are often modeled with a two-dimensional flow due to the small ratio of the gap thickness to the plane dimension in many applications.

Transverse permeability:

In-plane permeability:

Using preform in a cavity with varying thickness

Sometimes a preform is placed on areas with different thicknesses. A cavity with varying thickness, but reinforced with the same preform, can result in different porosity, and, therefore, permeability. To deal with this situation, specify the Reference thickness on which the preform properties were based. In the Properties tab of the Preform dialog, thickness is the reference thickness.

If the cavity thickness at molding is different from the specified reference thickness, the Reactive Molding analysis automatically modifies the porosity and permeability.