In the RTM (Resin Transfer Molding) and SRIM (Structural Reaction Injection Molding) analyses, resin is forced to flow through a cavity in which reinforcing preform (also called fiber mat) is present.

The flow type, characterized by the preform properties, may be isotropic or anisotropic depending on the preform structure. The resistance of a resin to flowing through the preform also depends on the resin properties and flow rate.

When preparing an RTM or SRIM analysis, the preform data includes:

- Porosity and permeability.

- Orientation, if the preform is anisotropic.

Isotropic preform

Resin flowing through a preform with random structure produces a circular melt front. This flow pattern is known as isotropic flow. This kind of preform normally is made from randomly chopped fiber strands; it is known as an isotropic preform. Since the resin flow pattern does not depend on the direction of flow, there is no need to specify the preform orientation.

For an isotropic fiber mat, the preform permeability in principal direction 1 is equal to the preform permeability in principal direction 2, and the preform cross permeability is zero. Therefore, in this product, you do not need to specify the orientation of an isotropic preform.

Anisotropic preform

If the structure of a directionally stitched or woven preform is not uniform, it is known as an anisotropic preform. In terms of the pore-area distribution, the preform shows a maximum in one direction and a minimum in the direction at right angles to the first direction. When resin flows through such a preform, the flow in the direction of maximum pore area advances more quickly, because it encounters less flow resistance. If the pore-area distribution is smooth, the melt front is elliptical.

The shape of the ellipse depends on the maximum and the minimum pore areas, which can be characterized by the permeability of the principal directions. The direction with the largest pore area, and thus the greatest permeability, is defined as Principal direction 1. Principal direction 1 corresponds to the major axis of the ellipse. The minor axis of the ellipse corresponds to principal direction 2, which is at right angles to principal direction 1 and has the smallest pore area and, thus, the smallest permeability.

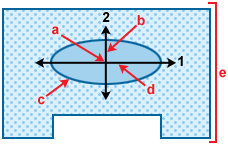

Schematic planar view of cavity, showing elliptic melt-front pattern for resin flowing through anisotropic preform:

- a is the resin inlet (gate)

- b is the minor axis

- c is the elliptic melt front

- d is the major axis

- e is the anisotropic fiber mat