When a CAD solid model is imported or opened, the Surface Splitting dialog can appear. Surface splitting is a process of recognizing where two parts have surfaces in contact, and then splitting the surfaces if necessary to get identical surfaces. The benefits of choosing to split the surfaces are as follows:

- The matching of the meshes on adjacent surfaces is better if the surfaces are identical. However,

- The Mesh

Mesh

Mesh 3D Mesh Settings

3D Mesh Settings Options

Options Model

Model Use virtual imprinting will create a quality matched mesh without using surface splitting. See the Model Mesh Settings: Model page for details.

Use virtual imprinting will create a quality matched mesh without using surface splitting. See the Model Mesh Settings: Model page for details. - For analysis types that support smart bonding, it is not strictly necessary to have a matched mesh. See the Types of Contact page for the analysis types that support smart bonding.

- The Mesh

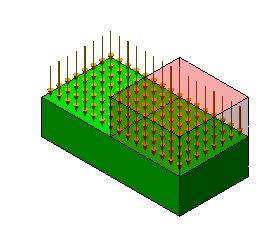

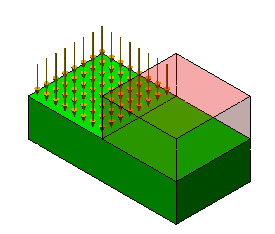

- Some loads should only be applied to free or exposed surfaces, such as pressure and convection. If a large surface is not split where it is covered by other parts, then the load will be applied to a larger area than intended. See the figures below.

The potential disadvantages of surface splitting are the extra time required when opening the model, and the possibility of generating surfaces which are harder to mesh than the unsplit surface. For example, a sliver surface can be created if the edges of two surfaces are close but not exactly aligned.

Options

Options CAD Import

CAD Import Global CAD Import Options and set the Split surfaces on import: option to Ask each time before opening the CAD model. If this option is set to Yes, the Surface Splitting dialog box does not appear but the operation is performed.

Global CAD Import Options and set the Split surfaces on import: option to Ask each time before opening the CAD model. If this option is set to Yes, the Surface Splitting dialog box does not appear but the operation is performed. When merging a CAD model into a CAD model, do not choose to split the merged model if the original model was not split.

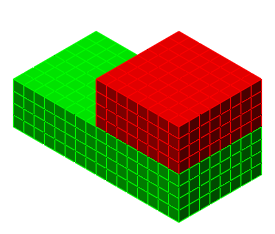

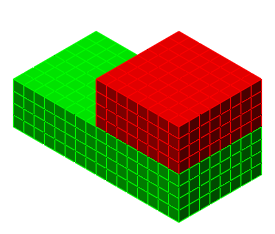

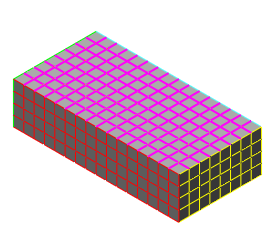

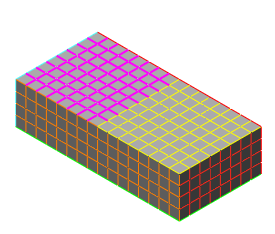

| Without Surface Splitting | With Surface Splitting |

|---|---|

|

|

| Two part assembly (color by part). | |

|

|

| Color by Part – Smaller part hidden for illustrative purposes (both images above). | |

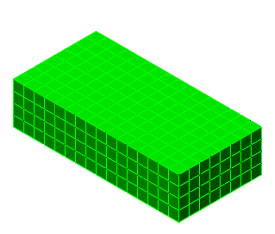

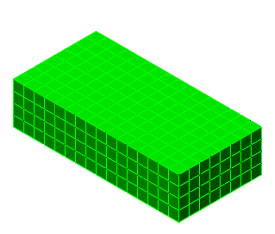

|

|

| Color by Surface – Top surface of large part is selected (magenta color). Note how the top is one big surface without using the surface splitting option. | Color by Surface – Top surface of large part is selected near the left end (magenta color). Note how the top is split into two portions when using the surface splitting option. |

|

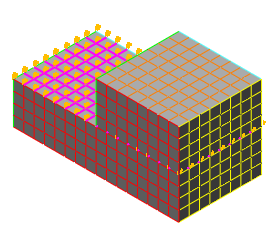

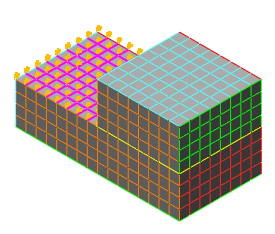

|

| A pressure load is applied to the selected surface on the larger part. It is easy to overlook that the load is applied underneath the smaller block in the model without surface splitting enabled (left image above). | |

|

|

| In the Results environment (with Transparency used on the smaller part), it can be seen that the pressure is applied over the entire face. | In the Results environment (with Transparency used on the smaller part), it can be seen that the pressure is applied over the intended region only. The pressure is not applied under the smaller part. |

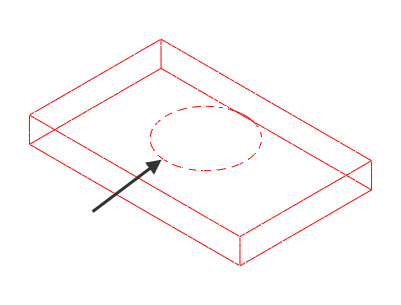

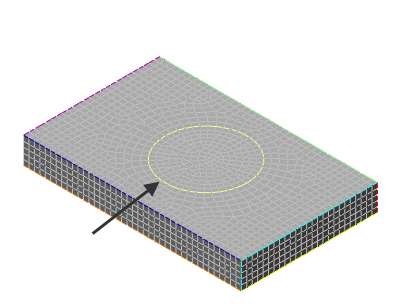

Although some CAD programs have the ability to split a face or surface into smaller regions, surface splitting provides an alternative method of creating a split face. (For those CAD packages that do not provide the ability to split a face, surface splitting in Autodesk Simulation Mechanical is the only practical method.) Imagine that the part being modeled is welded to a round support piece, and the support piece is not needed in the analysis. However, the pattern of the round support is needed in the mesh of the model to apply the boundary conditions. Using the surface splitting feature, the method of creating this would be as follows:

|

This is a wire frame view of one of the parts in a hypothetical analysis. Boundary conditions are desired along the circular edge within the top face of the rectangular part (to simulate the circular weld by which the rectangular part is mounted). Assume that the circular part is excluded from the CAD model and no circular feature is added to the rectangular part (such as by splitting the surface or adding a fictitious step or spotface). Without putting some kind of circular feature in the CAD solid model, the top of the rectangular part will be meshed with a pattern of rectangular elements. There will be no circle of nodes to constrain. |

|

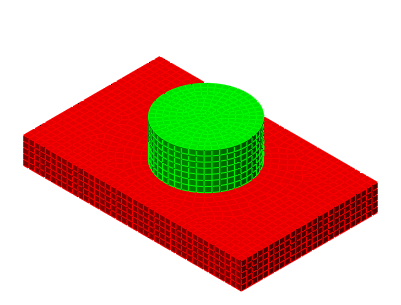

By including the circular part in the CAD solid model and importing this assembly into Simulation Mechanical, the circular pattern of nodes needed for the boundary conditions is automatically created. The default virtual imprinting feature of the mesh engine ensures that the meshes match between the two parts. However, there is still only one surface atop the rectangular part. In addition, when the circular part is suppressed in the FEA model, there is no circular edge to select for convenient application of the desired constraint. |

|

Finally, by enabling the Split surfaces on import option before importing the two-part CAD assembly, the rectangular face will be split into two surfaces—a rectangle with a hole in it, and a circular surface. In addition, a new edge will be added to the rectangular part (corresponding to the perimeter of the round part, shown in yellow). This circular edge makes it very easy to apply the desired boundary condition to the rectangular part. If a pressure were to be applied instead of a boundary condition, the circular area could also be selected (when surface splitting has been performed). Since the support is not required in the analysis, it can be suppressed in the FEA Editor. |

When you open a CAD model while the surface splitting prompt is enabled, you have an option to turn surface splitting off permanently (by checking Do not ask this question again. If this prompt is deactivated, it can be re-enabled from the Options dialog box (

Options

Options  CAD Import

CAD Import  Global CAD Import Options). Choose the Ask each time option to do so.

Global CAD Import Options). Choose the Ask each time option to do so.