To run a Cool (FEM) analysis for two-shot sequential overmolding, you require all the mold components in addition to the model components.

Cool (FEM) for two-shot sequential overmolding is supported for the following mesh types:

3D

3D

and for the following Cool (FEM) options:

- Averaged within cycle

- In cycle transient

- Production startup

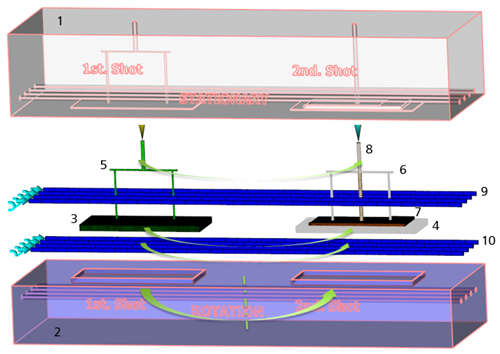

When running injection molding simulations, a mold cooling analysis is essential for two purposes: it provides a numerical tool for cooling system design, and it provides thermal boundary conditions for subsequent filling and packing analyses. The Cool (FEM) analysis predicts the mold temperature during the two-shot overmolding process by taking the rotational behavior of the rotating platen of the mold into account. This requires rotating meshes and changing thermal contact.

The cooling analysis for overmolding requires the entire mold layout to be modeled, including the

- Stationary platen

- Rotating platen

- First shot part component

- Overmolded part component

- First component feed system (optional)

- Overmolded component feed system (optional)

- Second shot part component

- Second shot feed system (optional)

- Cooling channels for stationary platen (if required)

- Cooling channels for rotating platen (if required)

Example mold components for Cool (FEM) for overmolding analysis

Once the setup is ready, the cool solver solves the two shots simultaneously. During the mold open stage, the final part is ejected from the second shot position. The mold plate is rotated to bring the first shot part into the second shot position, and the next shot analysis starts.