All required input files listed in this example can be retrieved by executing the following command:

$ pan -t 05

After the above command is executed, a directory named 05 is created, containing all files.

Problem description

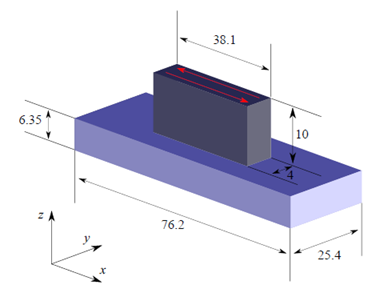

A two-bead wide, fifty-layer high Ti-6Al-4V wall is deposited onto a substrate of the same material using the Optomec® LENSsystem. The dimensions of the part are shown in Figure 5.1. For each layer, the first bead is deposited along the +x direction, then the second bead is deposited in the−x direction. The radius of the melt pool is 1 mm, its power is 450 W, and the translation speed is 10 mm/s. The hatch spacing between the two beads is 2 mm. The ambient temperature during the process is 30.5o C. The substrate is constrained as simply supported. The thermal and mechanical response of this process is to be calculated using Project Pan with adaptive meshing. The mesh, shown in Figure 5.2, is created automatically using the *AUTM and *SBXY cards.

Figure 5.1: Illustration of the substrate, deposition, their dimensions in mm, the laser path (red arrows), and the coordinate system (not to scale)