Thermal analysis

In the 05 directory, use a text editor to create the files named fin.in and fin_path.lsr with the contents shown in "Local Simulation Input Files" for Example 5. Run the analysis from the command line:

$ pan -b fin

After the analysis completes, the last few lines of the output file fin.out should be similar to the following:

inc = 4100 time = 500.00000 iter = 1 eps = 0.47875E+01 inc = 4100 time = 500.00000 iter = 2 eps = 0.14060E+01 inc = 4100 time = 500.00000 iter = 3 eps = 0.73374E-01 inc = 4100 time = 500.00000 iter = 4 eps = 0.20848E-03 Increment end Analysis completed CPU wall= 223.3203 CPU total= 4454.921 END PROJECT PAN

Mechanical analysis

In the 05 directory, use a text editor to create the file named fin_mech.in with the contents shown in "Local Simulation Input Files" for Example 5. Run the analysis from the command line:

$ pan -b fin_mech

After the analysis completes, the last few lines of the output file fin_mech.out should be similar to the following:

inc = 4167 time = 500.00000 iter = 1 eps = 0.81453E+04 inc = 4167 time = 500.00000 iter = 2 eps = 0.48872E+04 inc = 4167 time = 500.00000 iter = 3 eps = 0.31306E-09 Increment end Analysis completed CPU wall= 433.6602 CPU total= 8417.543 END PROJECT PAN

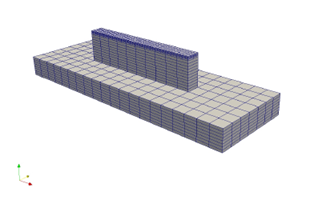

Figure 5.2: LENS part discretized by 8-node linear hexahedral elements. Dummy boundary conditions, materials, and properties must also be applied.

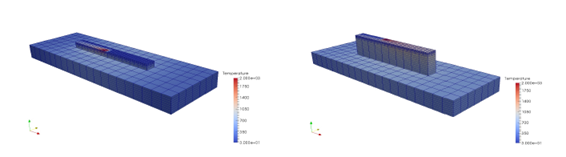

Figure 5.3: Temperature results (oC) during the deposition of the final layer.

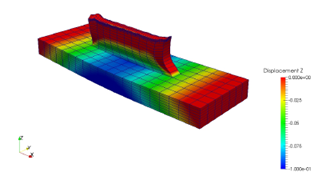

Figure 5.4: Post-process z distortion (5x magnification)

The results can be viewed in ParaView by importing the CASE files.