All required input files listed in this example can be retrieved by executing the following command:

$ pan -t 03

After the above command is executed, a directory named 03 is created containing all files.

Problem description

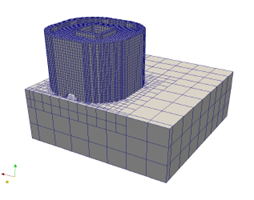

A generic geometry of Inconel 625 is built in a powder bed system and simulated. The layer height is 0.04 mm. The part geometry is imported in the analysis through an STL file, and it is automatically meshed within Local Simulation. The build plate is modeled to be 25 mm thick and 60 mm x 60 mm in area as defined in the *SBDM option. The time to deposit layers is calculated using the *PBDL card. The substrate is fixed to a circular rod defined using the *FIXC card. A controlled temperature of 200o C is applied to the build plate using *PBSH. The resulting mesh is illustrated in Figure 3.1.

Figure 3.1: Mesh

A time incremental thermal analysis is performed first to compute the temperature history of the part. Layers are activated in groups using *PBPA, and additional time increments are used to model heat conduction into the part. The thermal analysis includes only the part and substrate. Heat loss into the powder is modeled as convection with a value of 25.d-6 W/((mm2)–degC) using *CONV.