With conventional machining, the feed rate is set at a constant speed determined by the most demanding aspect of the toolpath. The Optimize Feed Rates option analyses the toolpaths created in ArtCAM and adjusts the feed rate to give a constant rate of material removal. Benefits include:

- A higher feed rate for lighter cuts and air moves, enabling faster machining.

- A more consistent cutting-tool load, reducing machining-spindle and tool wear. This also produces a better surface finish, which improves quality and reduces the time and cost of hand-finishing .

- A reduction in the feed rate as the cutter enters and leaves the material, which reduces tooling costs and the need to fit replacements. Similarly, protecting the machine tool reduces maintenance costs and limits down time.

- A reduced need for manual adjustment of the feed rate and a reduced need for operator supervision.

To optimise the feed rate in calculated toolpaths:

- Click the

Batch Calculate Toolpaths

button to display the

Batch Calculate Toolpaths dialog.

button to display the

Batch Calculate Toolpaths dialog.

- Select Optimize Feed Rates. The Toolpaths Available For Calculation area displays the names of calculated toolpaths in black and the names of uncalculated toolpaths in red.

- In the

Toolpaths Available For Calculation area, select the toolpaths you want to optimize. You cannot optimize the feed rate of uncalculated toolpaths.

Important: You cannot optimize the feed rate in a calculated Drill Bank toolpath. If any Drill Bank toolpaths are selected, a message is in the Status area confirms these toolpaths are ignored.

- If you want to adjust the optimization settings, click Settings to display the Optifeed Parameters dialog.

- Click the

Start button to optimize the selected toolpaths. If you want to cancel the process, click

Stop.

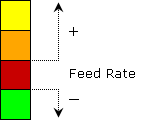

The effects of the optimization process on the toolpaths are shown in the 3D view:

- Yellow indicates the feed rate is increased by more than twice its original speed.

- Orange indicates the feed rate is increased by up to twice the original speed.

- Red indicates the feed rate is unchanged.

- Green indicates the feed rate is reduced.

Tip: You can also check the results of the optimisation process in the

Toolpath Summary Information dialog and compare the speed of the

Machining Time against the

Optifeed Time.