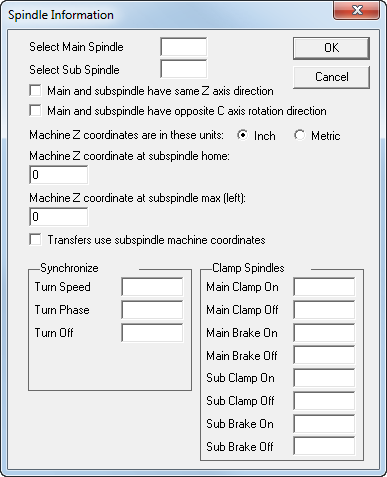

Contains the M codes for selecting the spindles. The Spindle Information dialog is displayed.

You can specify the following parameters:

Select Main Spindle — Enter the code for selection of the main spindle.

Select Sub Spindle — Enter the code for selection of sub spindle.

Main and sub spindles have the same Z axis direction — Select this option if the Z directions are the same for both spindles.

Main and sub spindles have opposite C axis rotation direction — Select this option if the main and sub spindles rotate in opposite directions, or deselect if they rotate in the same direction.

Machine Z coordinates are in these units — Select the unit system for the machine Z coordinates.

Machine Z coordinate at sub-spindle home — Enter the value for Sub Z home (typically zero).

Machine Z coordinate at sub-spindle max (left) — Enter the value for Sub Z max (from machine builder).

Transfers use subspindle machine coordinates — Select this option to position cutoff transfers and part handling features relative to the subspindle instead of to the part coordinates.

Translate Z coordinates after bar pull/rechuck — When this option is selected, Z coordinates are shifted by the amount of the bar pull or rechuck, and the <STOCK-POS> reserved word is shifted. If this option is deselected, <P-PULL-DIST>, which keeps track of the cumulative bar pull/rechuck amount, is zero.

The Synchronize Spindles section has these options for synchronizing spindles:

- Turn Speed — Enter the code for synchronizing the speed on both spindles.

- Turn Phase — Enter the code for synchronizing the phase on both spindles.

- Turn Off — Enter the code for turning off spindle turn synchronizing.

In the Clamp Spindles section, enter the codes for controlling the spindle clamps and brakes.