Each joint type fully defines the location and motion of the selected components. You can select end, mid, or center point geometry to define a joint. You can also set the joint relationship conditions using Lock and Protect.

Tip: The most common joint type is Rigid which positions a component and removes all degrees of freedom. Welded and bolted connections are examples of Rigid connections.

On the ribbon, use Assemble tab  Relationships panel

Relationships panel  Joint

Joint  to place a joint between two assembly components.

to place a joint between two assembly components.

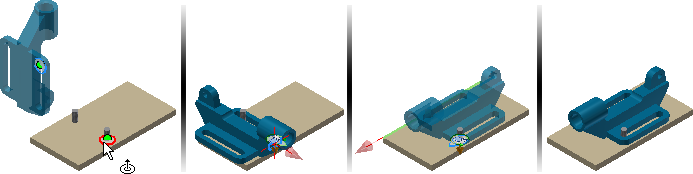

Use Joint to position components and define motion

To begin, place the components in an assembly file.

- Start the Joint command.

The default connection type is Automatic. Automatic determines the joint type based on the following rules:

- Rotational is selected if the two selected origins are circular.

- Cylindrical is selected if the two selected origins are points on a cylinder.

- Ball is selected if the two selected origins are points on a sphere.

- Rigid is selected for all other origin selections. Note: A Slider connection cannot be specified using a selection rule.

Select the origin on the moving component. Tip: Click Ctrl after the necessary component highlights to limit selection to the component.

Select the origin on the moving component. Tip: Click Ctrl after the necessary component highlights to limit selection to the component.-

The default origin selection is inferred directly from the geometry. For origin that cannot be inferred directly, make a selection from the context menu:

- To create a joint origin between 2 faces, select Between Two Faces, and specify a virtual midpoint between two faces, by selecting two faces and one point.

- To create a joint origin and position it an offset distance from the origin, select Offset Origin. Drag the manipulator arrows or input offset value to change the Origin location. Pick a reference geometry to align the Origin with.

Select the origin on the stationary component.

Select the origin on the stationary component. - If necessary, change the joint type.

If necessary, use Flip component to reverse the positive direction.

If necessary, use Flip component to reverse the positive direction.  If necessary, select Align 1 and pick one of the following to specify the alignment direction:

If necessary, select Align 1 and pick one of the following to specify the alignment direction: - A planar face, point, or edge on the moving component.

- A work plane/work axis/work point from the browser or the graphic window(if visible). If Align 1 is point selection(sketch point or work point), Align 2 must also be point selection.

If necessary, select Align 2 and make a selection on the stationary component to specify the alignment direction.

If necessary, select Align 2 and make a selection on the stationary component to specify the alignment direction.  To change the alignment direction, select Invert alignment.

To change the alignment direction, select Invert alignment. - Click Apply or OK to complete the operation.

Use Limits to define range of motion

To define a limit:

- Create or edit a joint.

- Open the dialog box. and click the Limits tab. Tip: If the dialog box is not available, press the three dots in the min-toolbar to display.

The availability of the Angular or Linear options depends on the joint type. For example, a Rotational joint supports Angular limits, but Linear limits are not available.

Note: Limits are not available for Rigid joints. - Set the necessary Start, Current, and End values.

- Click OK.

A relationship with a defined limit is marked with a +/- symbol in the browser.

Lock or Protect joint

- Lock a relationship to maintain the current position. Lock differs from grounding a component. Grounding eliminates all degrees of freedom, and fixes the component position in space. Lock eliminates all motion, but allows the component to change position when related components move.

- Protect a relationship to warn if added relationships violate the necessary degrees of freedom.

Lock or Protect relationship:

- Locate the relationship in the browser.

- Right-click the relationship, and select Lock or Protect in the context menu.

- To remove the condition, clear the check mark.

Note: Lock and Protect are not available for constraints.