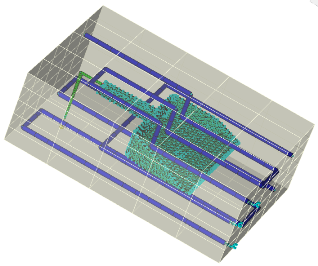

To run a Transient Cool analysis, in addition to the part model, you need the mold model with its associated cooling channels, hoses, baffles, etc. and any additional components, such as mold inserts. If you don't have a mold model, you can use the Mold Block Wizard to create one.

The Mold Block Wizard enables you either to generate a mold block as a region, or to create a CAD mold. In either case, the cooling channels and feed system must be represented by underlying curves in order to be included in the mold generation.

Mold block as a region

Mold block as a region is the default setting. When you click

Mold Block Wizard, a message appears indicating that you are generating the mold block as a region. Inspect the dimensions, and adjust them if necessary, until you are satisfied. You can create a CAD mold block subsequently if you wish.

Mold Block Wizard, a message appears indicating that you are generating the mold block as a region. Inspect the dimensions, and adjust them if necessary, until you are satisfied. You can create a CAD mold block subsequently if you wish.

CAD mold block

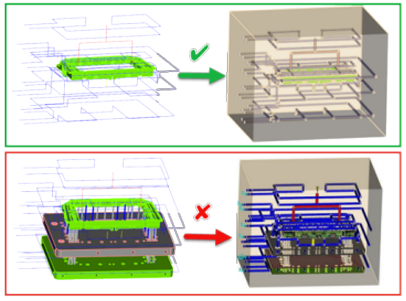

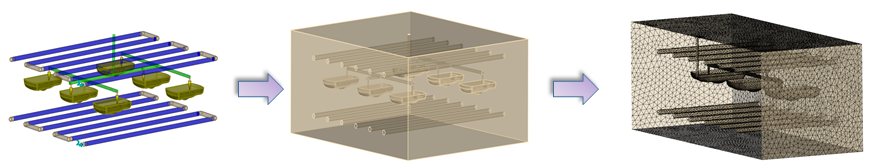

This option is available for CAD formats only. Generating a CAD mold using Mold Block Wizard simplifies the next step of meshing the mold:

- It enables the use of

Auto-sizing option in the

CAD tab of the

Mold Mesh tool. This option set automatically appropriate edge lengths on the internal and external faces of the mold.

- A merge tolerance option is available in the Mold Block Wizard dialog, to avoid the use of manual stitch contact interface later on.

- The internal components like inserts, parts, runner system and cooling system, are subtracted and a simplified cuboid mold is created.

You can create a CAD mold block in a single step, or you can create a mold block as a region, confirm that it is satisfactory, and then create a CAD mold from it. Generating a CAD mold in a single step, successfully, depends on the cleanliness of the part and insert. If the CAD part/insert has geometrical errors, it is likely that the CAD mold block generation will fail, or succeed with errors. Because it is important that your part/insert have no geometrical errors, CAD mold block generation is not set as the default option.