You can select to trigger the valve gate by ram position, either when creating a valve gate controller, or by editing an existing valve gate controller.

- Click

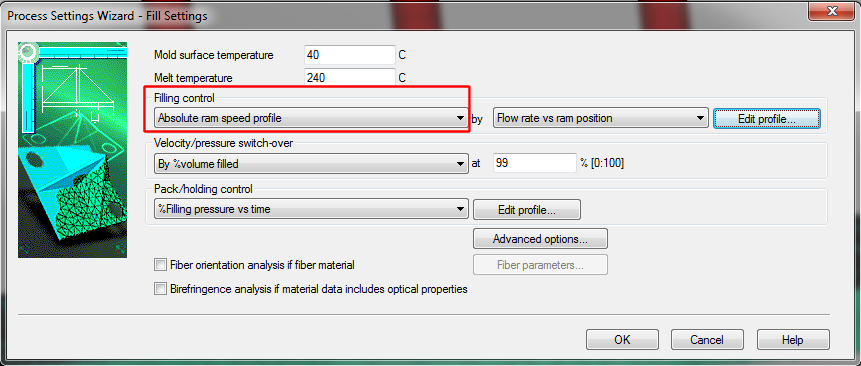

() and select a

Filling control option that includes a ram speed profile.

() and select a

Filling control option that includes a ram speed profile.

- Click

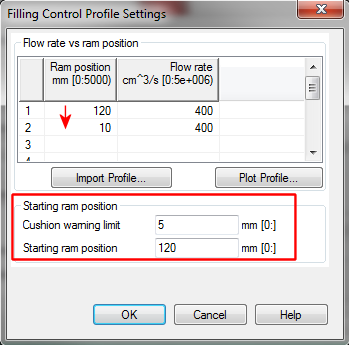

Edit profile and either check or enter appropriate values in the

Filling Control Profile Settings dialog. These values must be consistent with the valve gate controller profile you create later.

Specifically, ensure that:- the values you enter in the table for the Ram position, are entered in order of decreasing value,

- the

Starting ram position values are consistent with the valve gate control values you set later, for example

- Click OK to close the Filling Control Profile Settings dialog.

- Click OK to close the Process Settings Wizard dialog.

- Click

() to open the

Create/Edit Valve Gate Controller dialog.

() to open the

Create/Edit Valve Gate Controller dialog.

- Either

- Select an existing controller from the table and click Edit, or

- Click New.

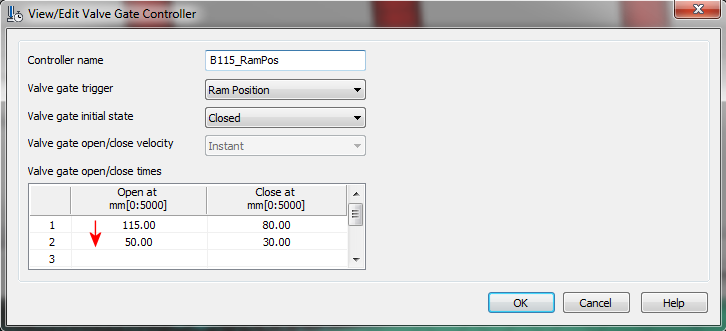

- In the Valve gate trigger drop-down menu, select Ram Position.

- Enter appropriate values in the Valve gate open/close times table, and ensure that they are consistent with the values you entered in the Process Settings dialog earlier.

- Click OK to close all the dialogs.

Attention: For a multi-barrel thermoplastics injection molding simulation, valve gates triggered by ram position are specific to the barrel attached to the same hot gate. The software automatically identifies the injection node for the associated barrel. You cannot attach the valve gate to one hot gate and specify a barrel associated with a different hot gate. Make sure you set up the valve gate appropriately for the associated barrel.