Valve gate controllers are required to control the opening and closing of valve gates associated with hot runner systems. The more control you have over the valve gates, the better the appearance of the part, but the more expensive the system.

Valve gates can be opened all at the same time, or sequentially. Some controllers are ideal for regular molding machines without sequential fill capability. Each control zone can be programmed for time-based and/or volume-based injection. Sequentially controlled valve gated systems are often necessary to achieve ideal part quality in large part applications.

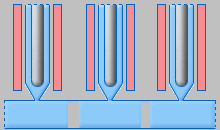

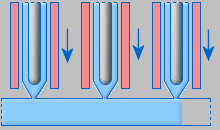

All three valve gates open co-temporally, forming weld lines where the different feeds meet.

Valve gates open simultaneously

(A)

(B)

(B)

(C)

(C)

(D)

(D)

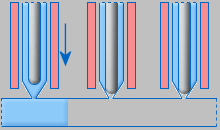

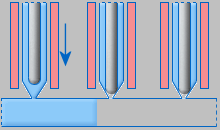

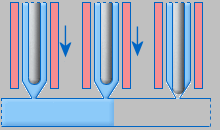

(A) 1st valve gate opens to allow melt to flow into the cavity, (B) melt continues to flow through the 1st gate only, (C) once the melt passes the 2nd gate, the 2nd valve gate opens to allow melt to flow through the 2nd gate, (D) when melt passes the 3rd gate, the 3rd valve gate opens to enable flow to enter the cavity from the 3rd gate, too.

Valve gates open sequentially

In addition to sequential or co-temporal valve gate opening, some valve gates open instantly, while some valve gates can be programmed to open in a velocity controlled manner to slow the initial flow of melt into the cavity and reduce pressure peaks and flow marks associated with instant opening. The combination of controlled valve gate opening with sequential valve gating provides the highest quality molding surfaces of all.

(

(