In this operation, the Horizontal strategy is used to finish the horizontal features of the part.

- On the ribbon, click

CAM tab

3D Milling panel

3D Milling panel

Horizontal

Horizontal

.

.

Tool tab

Tool tab

- Make sure that #14 - Ø5 R0.5 mm bullnose is still the current tool.

Heights tab

Heights tab

- Click the Heights tab.

- From the Top Height drop-down menu, select Model top.

- Change Top offset: to: -1 mm

With the Top offset value set to 1 mm under the top plane of the part, the tool only machines the inside cavities of the part and not the upper surface.

Note: Alternatively, the top surfaces could be excluded in an Avoid surface selection.

Passes tab

Passes tab

The previous adaptive clearing operations left a maximum of 0.3 mm (Stock to leave) + 1 mm (Fine stepdown) + 0.1 mm (Tolerance) = 1.4 mm of material. This is a little too much material for the tool to remove in one pass, so we will do it in three 0.4 mm passes instead.

- Click the Passes tab.

- Enable the Axial offset passes check box.

- Set Maximum stepdown: to: 0.4 mm

- Change Number of stepdowns: to: 1

Linking tab

Linking tab

- Click the Linking tab.

- From the Retraction policy: drop-down menu, select Minimum retraction.

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

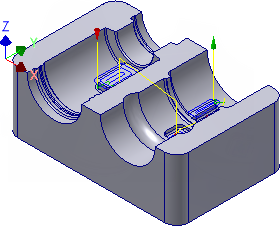

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Finish Steep Areas with Contour...