The machining begins with a facing operation to clear the top face of the stock and ensure that it is completely flat.

- On the ribbon, click

CAM tab

2D Milling panel

2D Milling panel

Face

Face

.

.

Tool tab

Tool tab

- On the Tool tab, click

.

. - From the Sample Libraries > Tutorial tool library, select tool #1 - Ø50 mm face.

- Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Geometry tab

Geometry tab

- Click the Geometry tab.

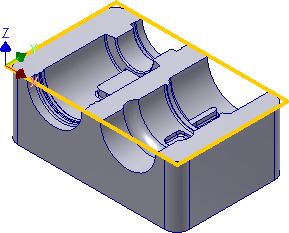

The Face strategy automatically detects the size of the stock as defined in the Setup. The stock profile is shown as an orange outline on the part.

Automatically detected stock size

Passes tab

Passes tab

The parameters on the Passes tab control how the actual facing toolpath is laid out. When the 50 mm tool was selected, the Stepover and Pass extension parameters were automatically updated to reflect the new tool diameter.

Leave the parameters at their defaults, except the Pass extension value which can be increased. This parameter specifies the distance to extend the passes beyond the machining boundary.

- Click the Passes tab.

- Change Pass extension: to: 5 mm

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

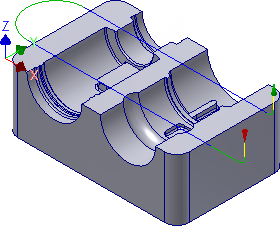

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Perform Outside Contouring (2D)...