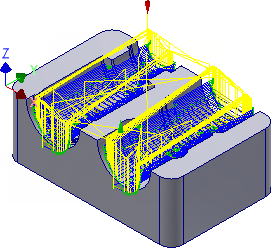

Use the Adaptive Clearing strategy to rough out the bulk of material. Adaptive clearing is a modern HSM (High Speed Machining) strategy designed for roughing on modern machines capable of running complex NC files at high speeds.

The defining parameters in Adaptive Clearing are the Optimal load and Stepdown settings. Traditional roughing strategies require you to set the load (or stepover) and stepdown for the worst case scenario. Adaptive clearing allows you to use the recommended maximum values provided by your tool vendor. This is possible since the specified Maximum Load is guaranteed not to be exceeded.

- On the ribbon, click

CAM tab

3D Milling panel

3D Milling panel

Adaptive Clearing

Adaptive Clearing

.

.

Tool tab

Tool tab

- Click

to open the Tool Library.

to open the Tool Library. - From the Sample Libraries > Tutorial tool library, select #11 - Ø10 R1 mm bullnose.

- Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Geometry tab

Geometry tab

By default, the Adaptive Clearing strategy does rest machining from the setup stock. Some of the stock has been removed from the previous operations; so to avoid having the adaptive clearing strategy remove the same material, we need to specify that rest machining should take the previous operations into account.

- Click the Geometry tab.

- From the Rest material source: drop-down menu, select From previous operation(s).

Leave the other settings on this tab unchanged.

Passes tab

Passes tab

The parameters in this group control the adaptive clearing passes. In this exercise, the default parameters work well. Generally, however, you will need to look up the values for the stepdown and load parameters in your tool catalog.

The Stock to Leave parameter controls the amount of material to leave in the radial (XY-plane) and axial (along the Z-axis) directions. The default values of 0.5 mm are suitable for this example, so leave them unchanged.

Start the Calculation

- Click

, or right-click in the graphics window and select OK from the marking menu, to exit Adaptive Clearing and create the toolpath.

, or right-click in the graphics window and select OK from the marking menu, to exit Adaptive Clearing and create the toolpath.

Continue to To Rest Machine Using Adaptive Clearing...