The tutorial starts with an Adaptive Clearing strategy to clear the elliptical shaped pocket.

- On the ribbon, click

CAM tab

3D Milling panel

3D Milling panel

Adaptive

Adaptive

.

.

Tool tab

Tool tab

- On the Tool tab, click the

button and select the tool #12 - Ø8 R1 mm bullnose from the Sample Libraries > Tutorial library.

button and select the tool #12 - Ø8 R1 mm bullnose from the Sample Libraries > Tutorial library. - Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Geometry tab

Geometry tab

Next, set the tool orientation and origin on the slanted face of the part.

- Click the Geometry tab.

- Enable the Tool Orientation check box to expand this group.

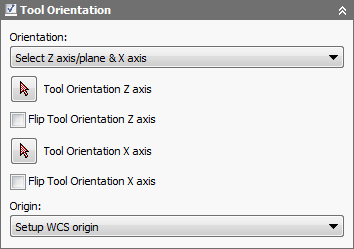

- Choose Select Z axis/plane & X axis from the Orientation: drop-down menu.

- Make sure the Tool Orientation Z axis button is active and select the slanted face as shown in the following image:

The slanted face of the part determines the new tool orientation

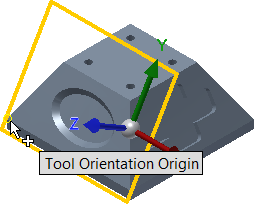

- It is now necessary to specify the direction of the X axis. Make sure that the Tool Orientation X axis button is active and select the horizontal edge of the part as shown below:

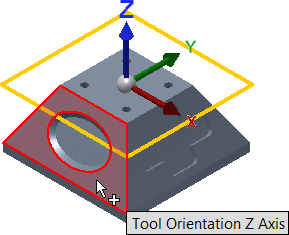

- The XYZ orientation of the tool is now correct, but the origin must be redefined. To do so, choose Selected point from the Origin: drop-down menu.

- Make sure the Tool Orientation origin button is active and select the point at the lower left of the part as shown below:

The new tool orientation and origin is now complete

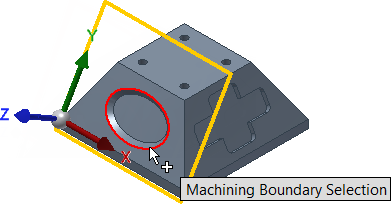

- For the machining boundary, choose Selection from the Machining boundary: drop-down menu at the top of the dialog box.

- Make sure that the Machining boundary selection arrow is active and, in the graphics window, click on the outer elliptical edge of the pocket to select it.

- Next, select Tool center on boundary from the Tool containment: drop down menu.

Now that the tool is in the correct orientation, the geometry can be selected.

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

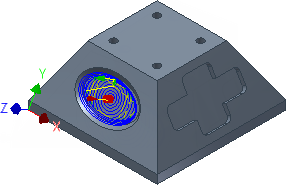

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Clear Using 3D Pocket...