There remains between 0.2 mm and 0.4 mm material left on the part (0.3 mm stock to leave plus/minus 0.1 mm tolerance). Several semi-finish operations will be used to reduce this material.

Use a Contour operation to handle the steep areas of the part.

- On the ribbon, click

CAM tab

3D Milling panel

3D Milling panel

Contour

Contour

.

.

Tool tab

Tool tab

- On the Tool tab, click the

button.

button. - Select the tool #20 - Ø10 mm ball from the Tutorial4 library.

- Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Geometry tab

Geometry tab

- Click the Geometry tab.

- From the Tool containment: drop down menu, select Tool center on boundary.

- Enable the Slope check box.

- Change From slope angle to: 60 deg

- Change To slope angle to: 90 deg

We want to confine the machining to steep areas with this operation. This can be achieved by limiting the slope range.

Passes tab

Passes tab

- Click the Passes tab.

- Set Tolerance: to: 0.02 mm

- Set Maximum stepdown: to: 1 mm

- Enable the Order by depth check box.

- Enable the Stock to Leave check box. Use the default values of 0.1 mm for this operation.

Linking tab

Linking tab

- Click the Linking tab.

- From the Retraction policy: drop-down menu, select Minimum retraction.

- Change Maximum stay-down distance: to: 10 mm

- Expand the Ramp group and change Ramping angle (deg): to: 10 deg

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

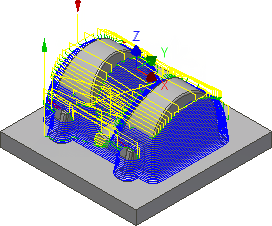

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Machine Shallow Areas Using Scallop...