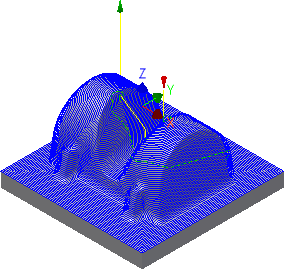

There is now 0.1 mm of remaining material on most of the part. There is a little more on top of the base surfaces, inside the 4 mm fillets, and on the lower part of the fillets at the base surfaces. A Scallop strategy is used to finish the part.

- On the ribbon, click

CAM tab

3D Milling panel

3D Milling panel

Scallop

Scallop

.

.

Tool tab

Tool tab

- On the Tool tab, click the

button.

button. - Select the tool #21 - Ø6 mm ball from the Tutorial4 library.

- Click

to close the Tool Library dialog.

to close the Tool Library dialog.

The slope range was limited in the previous operations to confine machining to steep areas. In this operation we want to machine the entire part in one go to obtain a consistent amount of stock left. Machining is performed down to the flat area of the part, omitting the rectangular base.

Passes tab

Passes tab

- Click the Passes tab.

- Set Tolerance: to: 0.02 mm

- From the Inside/outside direction: drop-down menu, select Inside -> out.

- Set Stepover: to: 1 mm

- Enable the Stock to Leave check box.

- Set Radial stock to leave to: 0.05 mm

- Set Axial stock to leave to: 0.05 mm (this value should update automatically)

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Machine the Base Surface Using Horizontal...