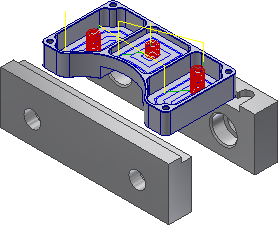

After roughing out the pockets, use a 2D Pocket strategy to create a finished cut.

- On the ribbon, click

CAM tab

2D Milling panel

2D Milling panel

2D Pocket

2D Pocket

.

.

Tool tab

Tool tab

- Make sure that #1 - Ø1/4" flat is still the current tool.

Geometry tab

Geometry tab

- Click the Geometry tab.

- Click the Pocket selections button and, once again, select the three faces at the bottom of the part.

Passes tab

Passes tab

On the Passes tab, change the following:

- Enable the Finishing passes check box.

- Stepover to: 0.025 in

- Finish feedrate to: 60 in/min

- Maximum stepover to: 0.125 in

- Disable the Stock to Leave check box.

Linking tab

Linking tab

Change these values on the Linking tab:

- Maximum stay-down distance to: 1.25 in

- Enable the Lead-in (entry) check box.

- Horizontal lead-in radius to: 0.025 in

- Linear lead-in distance to: 0.025 in

- Vertical lead-in radius to: 0.025 in

- Maximum ramp stepdown to: 0.625 in

- Helical ramp diameter to: 0.2375 in

- Minimum ramp diameter to: 0.2375 in

Start the Calculation

- Click

, or right-click in the graphics window and select OK from the marking menu, to exit 2D Pocket and create the toolpath.

, or right-click in the graphics window and select OK from the marking menu, to exit 2D Pocket and create the toolpath.

Continue to To Rough Cut the Outside of the Part...