Create two different types of support structures in Netfabb and test their performance in Simulation Utility.

Video length (5:49).

Sample files for use with the tutorials are available on the Download Page.

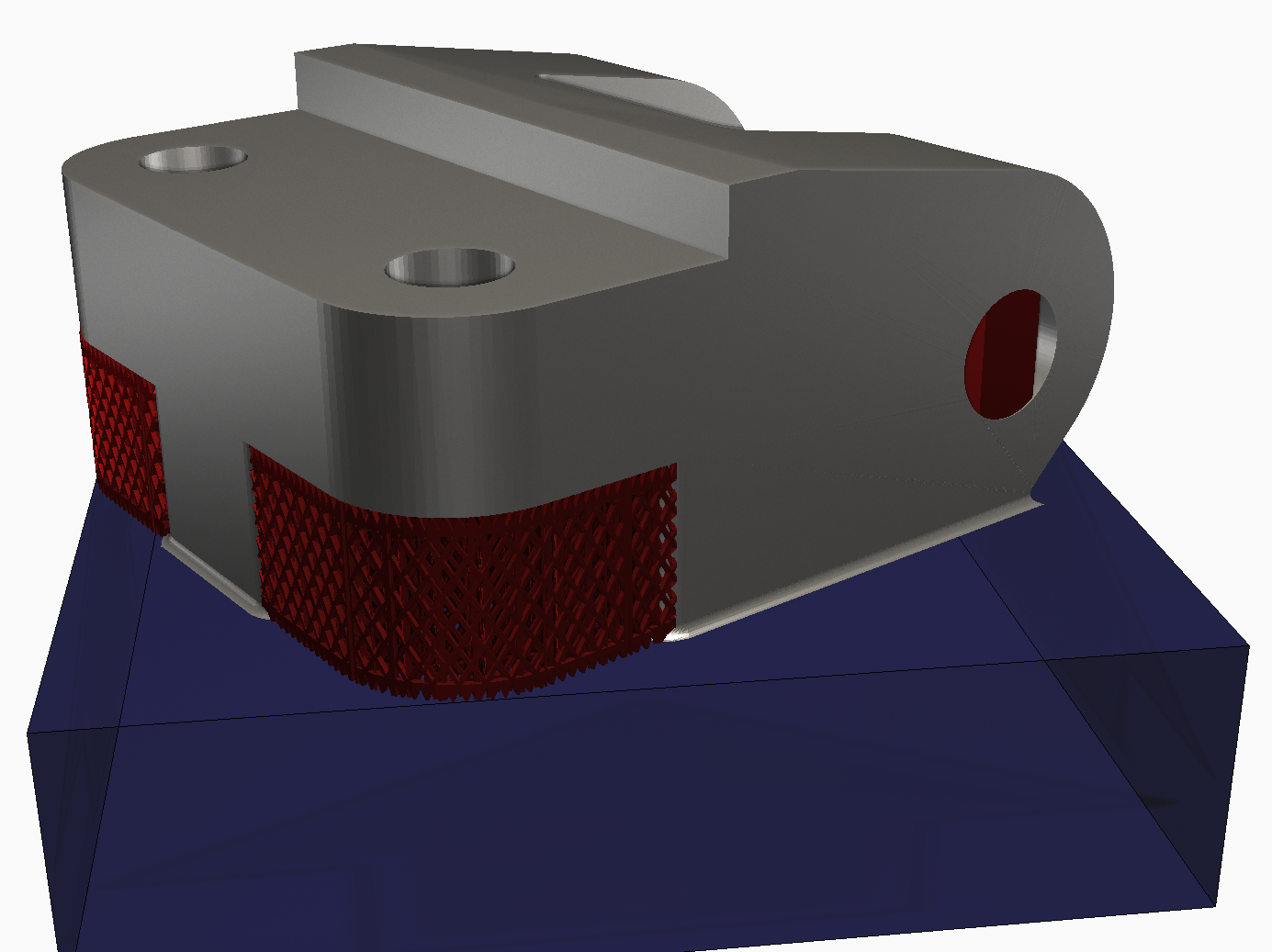

In some cases, users may want to simulate both the preferred homogenized type supports, covered in Tutorial 15, and also the actual fine structured support, on the same model. We will use Netfabb to create support structures for this part.

- In Netfabb, click .

- If it's not already there, add

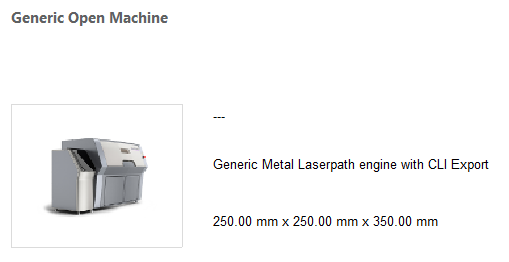

Generic Open Machine to your list of machines.

- In the My Machines dialog, click the Add Machine button.

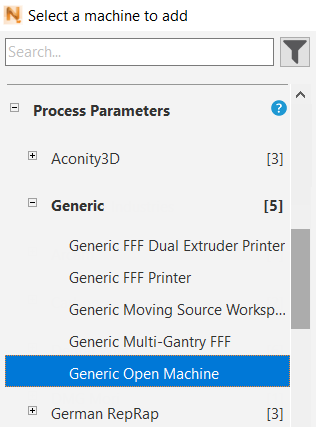

- In the

Select a machine to add dialog, scroll down the

Process Parameters list, expand the

Generic category, and click

Generic Open Machine.

- Click the Add to My Machines button at the bottom of the dialog.

- In the

My Machines dialog, with the machine selected, click

Open.

You should see Generic Open Machine selected at the top of the project model tree.

- Right-click and add the sample file Example_22.stl .

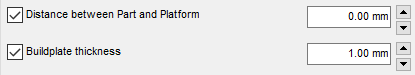

- In the left pane, note the check box for Distance between Part and Platform.

In the field to the right, set the distance to 0.00 mm and press Enter. The part must be seated directly on the platform for proper creation of support structures.

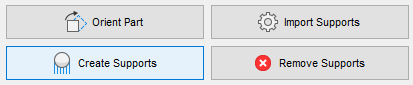

- Click

Create Supports.

- At the bottom of the window, click

Run Support Script, in the

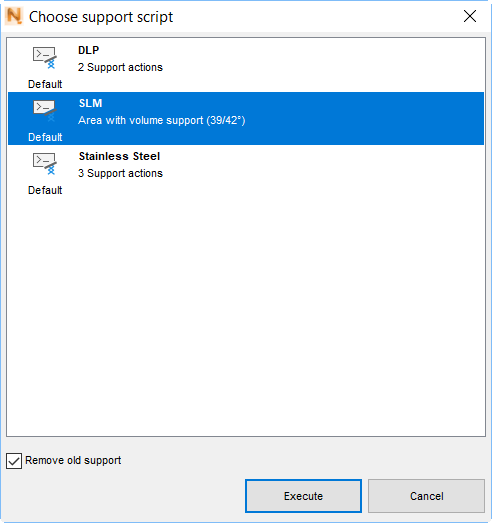

Choose support script dialog, select

SLM, and click

Execute.

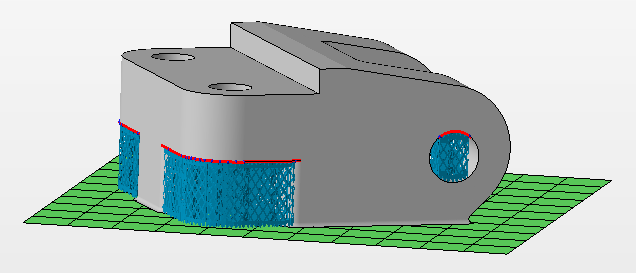

The lattice-like supports are created.

- For this instance, it is desired that only the back supports are homogenized. Right-click each of the two curved front supports and choose

Remove entity. You may need to do this more than once if you see bits of lattice remaining.

- Click Apply support.

- Click Start build simulation; in the dialog that opens, enter a suitable file path and name, such as Example_22, leaving in place the file extension .3mf. Click Save.

- In the

Start build simulation dialog, ensure that

Combine support volumes for simulation is checked, select the

Simulation Utility version, if both are available, and click

Simulate.

The exported file takes a minute or so to generate, then opens inside the Simulation Utility window.

- If you want to reduce the size of the build plate, click Build Plate, then in the Build Plate dialog, click .

- Return to Netfabb to add the lattice type supports. If the Start build simulation dialog is still open, press Cancel to close it.

- In the file tree, drag and drop the Example_22 part from the Generic Open Machine workspace to the Parts workspace.

- Click

Prepare menu >

Generate Support

.

.

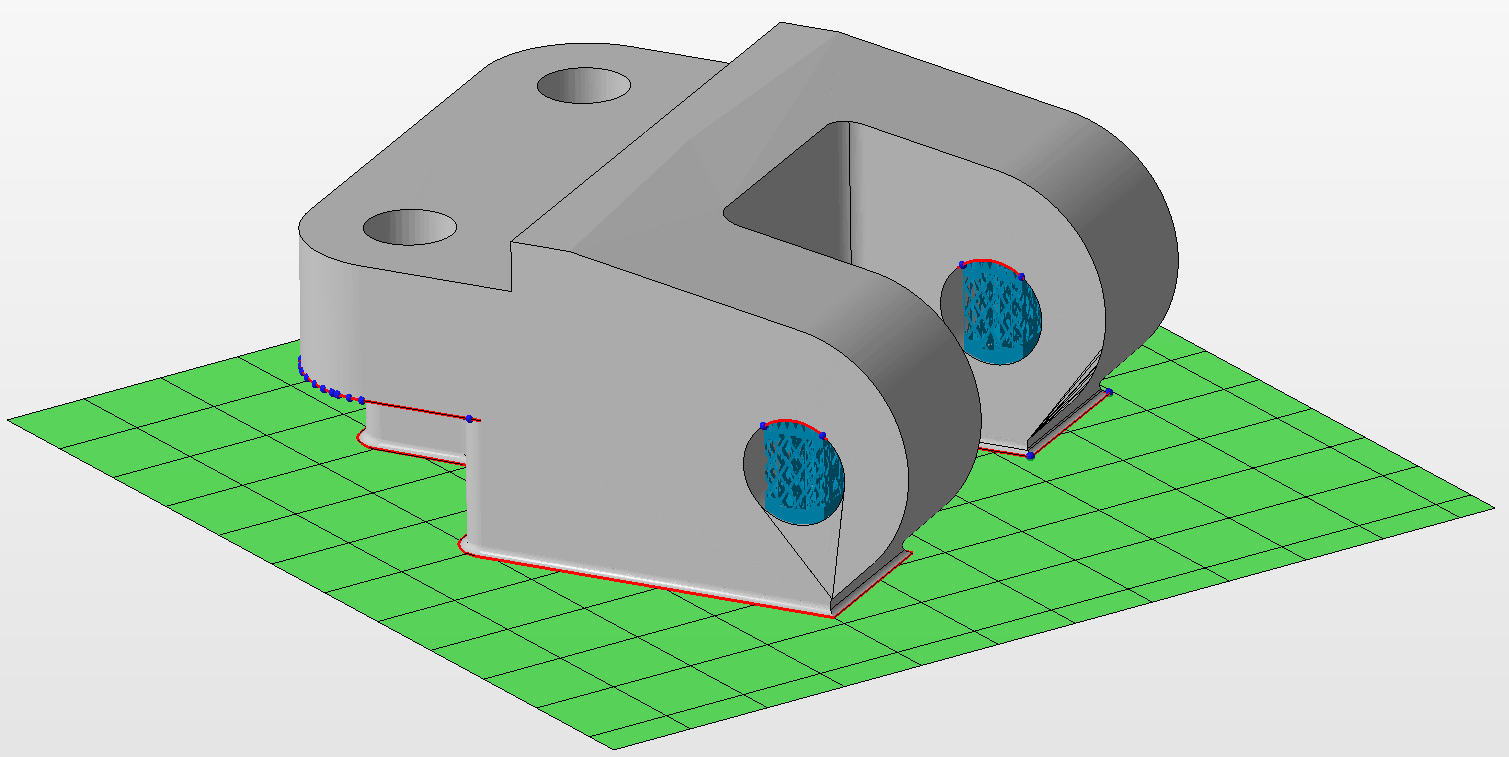

- Click Run Support Script at the bottom of the Support Window. Choose SLM type supports from the list and click Execute.

- Now delete the back supports which have already been generated and homogenized. Do this by right-clicking and selecting Remove entity.

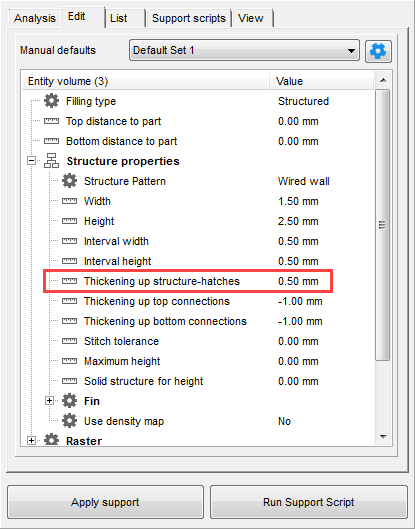

- A thickness must be added for the lattice supports to mesh. Select both curved supports by holding down the Ctrl button and clicking the left mouse button.

- Switch to the Edit tab in the left pane. Expand the Structure properties menu by pressing the + symbol.

- In the

Thickening up structure-hatches field, type

0.50. This will create support structure walls approximately 2-3 bead widths wide. Click

Apply support.

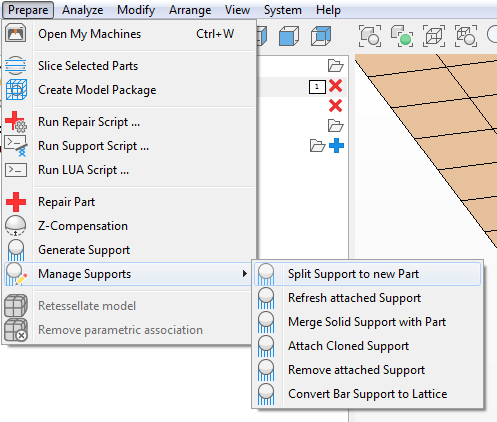

- To use in simulation, these supports must be turned into an STL file. Click

.

- Either in the file tree or canvas window, right-click on the new part with (support) in its name. Select . Navigate to the same folder where the first Example_22.3mf file was saved. Name the new file Example22_support.stl, click Optimize, and press OK.

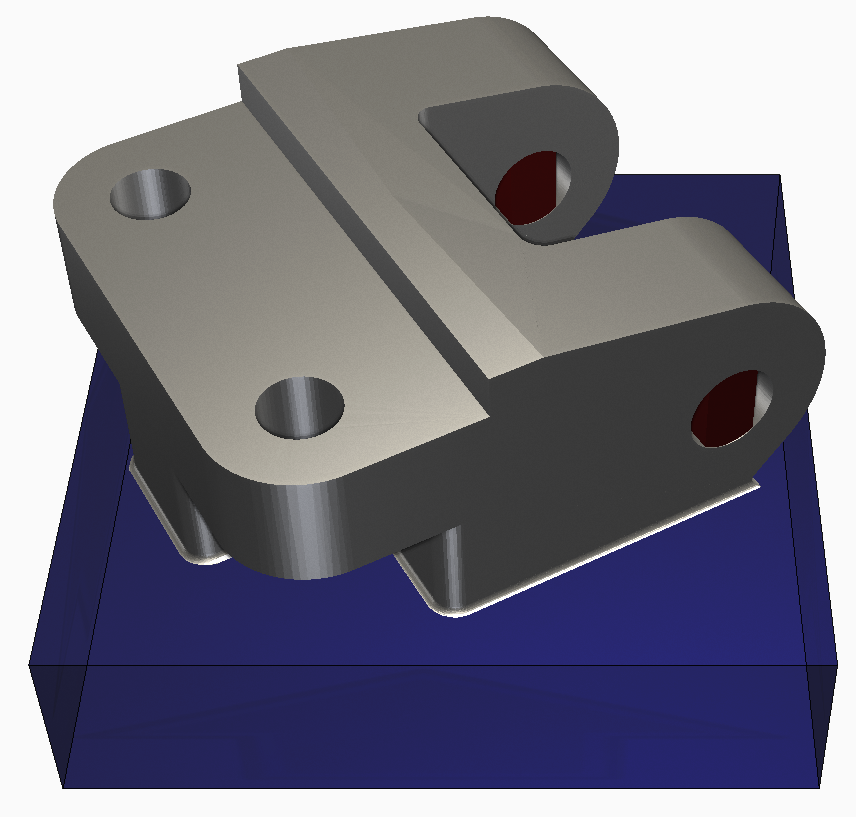

- Return to the

Simulation Utility window from step 11. From the Document panel on the Home tab, click

Import. Select the

Example_22_support.stl file just created. Designate this as a

Support Structure with a

Volume Fraction of

1.00 when prompted.

Now you have a part with two types of supports, and you can proceed to perform a simulation as outlined in previous tutorials.