In Netfabb, generate supports for use in Simulation Utility.

Video length (2:53).

In this tutorial, the concept of homogenization of support structures is shown, and it is demonstrated how to use Netfabb and Simulation Utility together for the efficient modeling of support structures.

Sample files for use with the tutorials are available on the Download Page.

Homogenization

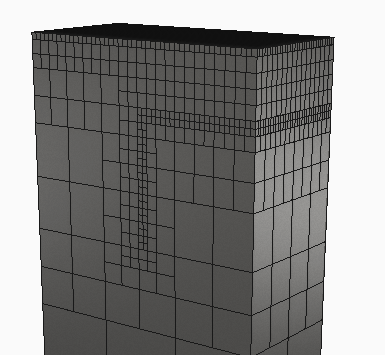

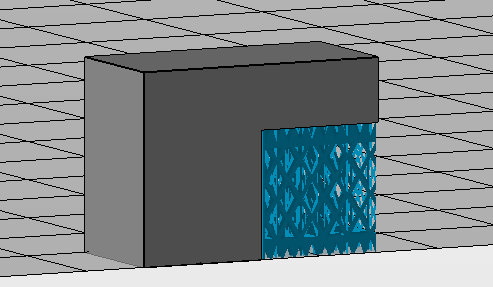

The first figure below shows lattice support structures. The volume fraction is small, meaning that only a small portion of the total volume of the support region is occupied by solid material. Meshing a fine lattice adds a significant number of small elements and thus degrees of freedom, which extends the run time of the simulation and increases the required memory usage.

![]()

![]()

To improve modeling efficiency, users are advised to always implement support structure homogenization. Homogenization uses a volumetric type support structure that fills the same volume as the support that will be printed. The volumetric support can be coarsely meshed which reduces both memory consumption and computational times. To ensure the homogenized structure will exhibit the same thermo-mechanical behavior, the material properties of the homogenized structure are scaled by the volume fraction of the nominal support structure. Consult the Documents page for further details about the homogenization process and how to manually calculate volume fractions for support structures generated outside of Netfabb.

To generate the supports in Netfabb

- Open the

Generic Open Machine workspace in one of two ways:

- Click , then in the My Machines dialog, click Generic Open Machine and click the Open button.

- If Generic Open Machine is not in the list of machines, add it to the list as follows:

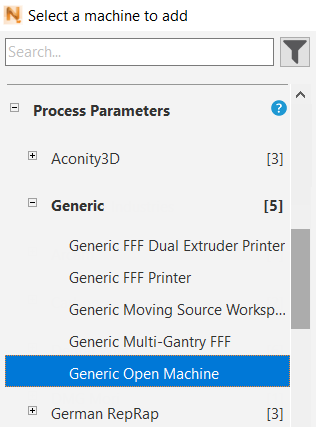

- In the My Machines dialog, click the Add Machine button.

- In the

Select a machine to add dialog, scroll down the

Process Parameters list, expand the

Generic category, and click

Generic Open Machine.

- Click the Add to My Machines button at the bottom of the dialog.

- In the My Machines dialog, click Generic Open Machine and click the Open button.

- Right-click and add the sample file Example_15.stl .

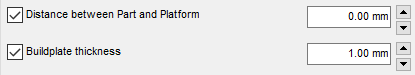

- In the left pane, note the check box for Distance between Part and Platform.

In the field to the right, set the distance to 0.00 mm and press Enter. The part must be seated directly on the platform for proper creation of support structures.

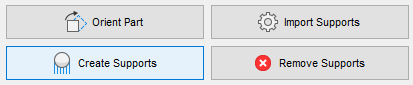

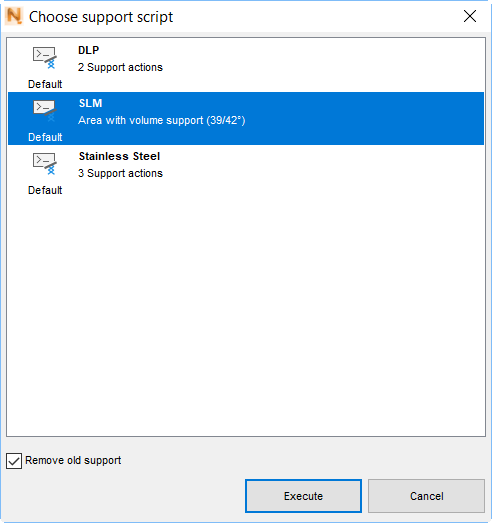

- Click

Create Supports.

- At the bottom of the window, click

Run Support Script, select

SLM, and click

Execute.

The lattice-like supports are created.

- Click Apply support.

- Click Start build simulation; in the dialog that opens, enter a suitable file path and name, such as Example 15, leaving in place the file extension .3mf. Click Save.

- In the

Start build simulation dialog, ensure that

Combine support volumes for simulation is checked, select the

Simulation Utility version, if both are available, and click

Simulate.

The exported file takes a minute or so to generate, then opens inside the Simulation Utility window on a large build plate. Note that the lattice support has been replaced with a solid block.

To modify the support in Simulation Utility

- On the Home tab, click .

- To resize the build plate, click the Snap to X and Y button.

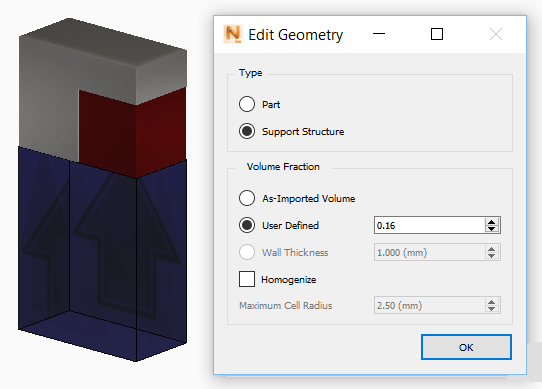

- In the Browser, right-click on the support structure, which has a name that includes

_hulledsupport_, select

Edit Geometry, and in the dialog, you see that

User Defined is selected by default.

Note that the Volume Fraction brought over from Netfabb was automatically calculated at 16%. Click OK. Next, generate a mesh preview to see the results of homogenization.

- On the Home tab, click

Mesh Preview and save the project in a suitable location.

Upon viewing the results observe that coarse mesh elements are used where the part and support are near the build plate, and fine elements along the interfaces between the part and support. This part will simulate in a much shorter time than if the original lattice like supports had been used, while attaining the same predictions of thermo-mechanical behavior during processing.